Micrograph Library

Browse the libraryAdvanced searchSystemsCompositionsTechniquesKeywordsPhase diagramsHelpPreferencesAbout the micrograph libraryTerms of useContribute micrographs!FeedbackLinksCredits Print this page

Full Record for Micrograph 242

[151 KB]

View micrograph

.. in new window

View micrograph and record

.. in new window

You can also view and download the micrographs on Flickr

- Micrograph no

- 242

- Brief description

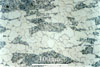

- Fe, C 0.3 (wt%) steel, spheroidised carbide

- Keywords

- alloy

, carbon, hypoeutectoid

, carbon, hypoeutectoid  , iron, metal, pearlite

, iron, metal, pearlite  , steel

, steel

- Categories

- Metal or alloy

- System

- Fe-C-X

- Composition

- Fe, C 0.3 (wt%)

- Standard codes

- Reaction

- Processing

- Spheroidised

- Applications

- Sample preparation

- Nital

- Technique

- Reflected light microscopy

- Length bar

- 100 μm

- Further information

- A hypoeutectoid alloy (composition less than eutectoid). The first phase formed upon cooling from the austenite phase field is proeutectoid ferrite. Due to the lower solubility of carbon in ferrite, carbon is partitioned into the remaining austenite. At the eutectic point the remaining carbon-enriched austenite transforms to pearlite (a mixture of ferrite and cementite), which is the darker region of the micrograph. The proportion of pearlite is dependent upon the overall composition.

Subsequent to casting the sample was annealed for a long period just below the transformation range. This induces the cementite to take on a spherical appearance. This results in a softer and more ductile alloy. This process is known as spheroidisation. The changes to the morphology of the cementite, compared with the normal plate-like appearance in freshly-formed pearlite, are clearly visible in this micrograph. - Contributor

- Dr R F Cochrane

- Organisation

- Department of Materials, University of Leeds

- Date

- 04/09/02

- Licence for re-use

Attribution-NonCommercial-ShareAlike 4.0 International

Attribution-NonCommercial-ShareAlike 4.0 International- Related micrographs