Micrograph Library

Browse the libraryAdvanced searchSystemsCompositionsTechniquesKeywordsPhase diagramsHelpPreferencesAbout the micrograph libraryTerms of useContribute micrographs!FeedbackLinksCredits Print this page

Full Record for Micrograph 575

[104 KB]

View micrograph

.. in new window

View micrograph and record

.. in new window

You can also view and download the micrographs on Flickr

- Micrograph no

- 575

- Brief description

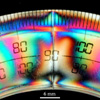

- Injection-moulded protractor

- Keywords

- alignment, birefringence

, injection moulding

, injection moulding  , polymer

, polymer  , polystyrene (PS), protractor, sprue, weld

, polystyrene (PS), protractor, sprue, weld - Categories

- Polymer

- System

- Polystyrene (PS)

- Composition

- Not specified

- Standard codes

- Reaction

- Processing

- Polystyrene was injected into a mould from a single point and has flowed round the component to meet at a noticeable 'weld line'

- Applications

- Polystyrene is hard and inexpensive and its use is very widespread. CD cases and clear plastic cups are common examples. Domestic appliance casings are also typically made from PS

- Sample preparation

- Technique

- Cross-polarised light microscopy

- Length bar

- 6 mm

- Further information

- The colours in the image are the result of birefringence and relate to the residual strain in the polystyrene. The pattern of strain is indicative of the flow of material during the injection process and it highlights a 'weld line' where two distinct flows of material meet. The weld line is a common point of failure because there is limited intermixing of the two fronts during the time allowed.

- Contributor

- J A Curran

- Organisation

- Department of Materials Science and Metallurgy, University of Cambridge

- Date

- 03/10/02

- Licence for re-use

Attribution-NonCommercial-ShareAlike 4.0 International

Attribution-NonCommercial-ShareAlike 4.0 International- Related micrographs