Micrograph Library

Browse the libraryAdvanced searchSystemsCompositionsTechniquesKeywordsPhase diagramsHelpPreferencesAbout the micrograph libraryTerms of useContribute micrographs!FeedbackLinksCredits Print this page

Full Record for Micrograph 711

[178 KB]

View micrograph

.. in new window

View micrograph and record

.. in new window

You can also view and download the micrographs on Flickr

- Micrograph no

- 711

- Brief description

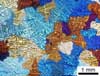

- As-cast wrought-grade aluminium alloy (Al-Mg-Fe-Si containing < 1wt.% of each solute). No addition of grain refinement particles (e.g. TiB2).

- Keywords

- alloy

, aluminium

, aluminium  , anodising

, anodising  , dendrite

, dendrite  , equiaxed

, equiaxed  , iron, magnesium, metal, silicon

, iron, magnesium, metal, silicon

- Categories

- Metal or alloy

- System

- Al-Mg-Fe-Si

- Composition

- Not specified

- Standard codes

- Reaction

- Processing

- As-cast

- Applications

- Sample preparation

- Electrolytically etched using Barker's reagent.

- Technique

- Cross-polarised light microscopy

- Length bar

- 1 mm

- Further information

- This micrograph illustrates one of the possible growth morphologies that a solidifying metal can adopt (c.f. micrograph 712). The dendritic structure is the result of instabilities in the solid-liquid interface during growth due to the rejection of solute into the liquid phase. Dendritic grains are more prevalent in alloys of high solute content and larger grain sizes.

The Barker's etch and applied electrical field produce a thick oxide layer on the grains of aluminium (anodising). When viewed in cross-polarised light, interference in the oxide layer produces colours which depend on grain orientation and oxide thickness; hence the grain structure is imaged. - Contributor

- T Quested

- Organisation

- Department of Materials Science and Metallurgy, University of Cambridge

- Date

- 20/01/03

- Licence for re-use

Attribution-NonCommercial-ShareAlike 4.0 International

Attribution-NonCommercial-ShareAlike 4.0 International- Related micrographs

- Micrograph 710: Wrought-grade aluminium alloy (Al-Mg-Fe-Si containing < 1wt.% of each solute); refined with TiB2 particles. Deformation of grain structure is due to cutting of sample with scissors. (400 μm)

- Micrograph 712: As-cast wrought-grade aluminium alloy (Al-Mg-Fe-Si containing < 1wt.% of each solute). Addition of TiB2 particles facilitates the formation of a fine, equiaxed grain structure (grain refinement). (400 μm)