Stress patterns: 4-point bending

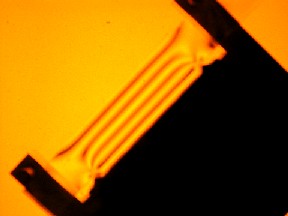

Plain bar

The bar within the inner loading span of the four point bending arrangement experiences a pure bending moment. Within this region the stress is parallel to the long edges of the bar but its magnitude varies across the bar from a maximum tensile stress at the outer (convex) edge, through zero on the neutral axis to a maximum compressive stress at the inner (concave) edge.

Between the two inner loading points on the bar is a region of pure bending. In the bar the longitudinal stress is a principal stress, there are no vertical or horizontal shear stresses and no transverse normal stresses. Therefore, if at a point P a distance y from the neutral axis there exists a stress which would cause a phase difference of one wave length, then all points on the horizontal line through P parallel to the longitudinal axis of the bar would cause the same phase difference.

When the applied load is increased the first areas to show photoelastic effects are the extreme edges of the sample, which are obviously under the greatest stress. As the stress is increased bands originate at the edges of the sample and travel inwards towards the neutral axis. The spacing between these bands becomes narrower as the load is increased but the bands remain straight and parallel to the neutral axis.

|

|

|

Annealed bars in 4-point rigs |

|

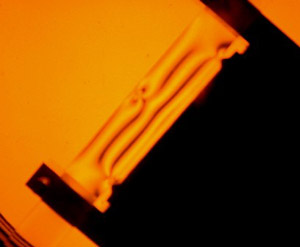

Bar with notch

The general stress distribution is similar to the normal specimen except in the vicinity of the notch where the stress pattern is distorted. The notch acts as a stress concentrator, focussing the stress at its tip. The concentration of stress is local because a few crack lengths away the stress returns to its pure bending distribution. Around the notch the isochromatic fringes bunch up indicating a stress concentration there. Around the notch the principal stress directions are altered and no longer lie parallel to the longitudinal and transverse directions of the specimen.

|

|

|

Annealed and notched bars in 4-point bending rigs |

|

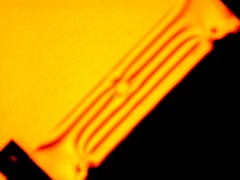

Bar with hole

As the applied load is increased, the bar behaves similarly to the plain sample. The hole is on the neutral axis, and therefore in the least stressed position. As the stress increases, the isoclinic fringes approach the edges of the hole, and for high stresses isochromatic fringes representing a high stress concentration can be seen around the edges of the hole, particularly in the transverse positions.

|

|

|

Annealed bars with holes in 4-point bending rigs |

|