Re-use of this resource is governed by a Creative Commons

Attribution-

NonCommercial-ShareAlike 4.0 International

https://creativecommons.org/licenses/by-nc-sa/4.0/

NonCommercial-ShareAlike 4.0 International

https://creativecommons.org/licenses/by-nc-sa/4.0/

Deformation

Twinning

Deformation

Twinning

Deformation twinning

When a stress is applied to a crystalline material deformation

occurs. The deformation can be absorbed by the material in several ways:

Slip

Crystal planes slide past each other by means of dislocations gliding through the material. Slip is an irreversible deformation. (In this animation, the actual dislocations are not shown, and all that is depicted is the fact that the strain is localised to specific planes, on which "sliding" occurs.)

Crystal planes slide past each other by means of dislocations gliding through the material. Slip is an irreversible deformation. (In this animation, the actual dislocations are not shown, and all that is depicted is the fact that the strain is localised to specific planes, on which "sliding" occurs.)

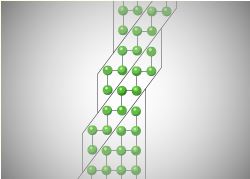

Deformation twinning

Each atom moves only a small distance relative to its neighbour but in a well defined way. (In this animation, the motion of atoms is shown taking place relatively slowly, whereas in practice it is very fast - ie at approximately the speed of sound in the material)

Each atom moves only a small distance relative to its neighbour but in a well defined way. (In this animation, the motion of atoms is shown taking place relatively slowly, whereas in practice it is very fast - ie at approximately the speed of sound in the material)

Click on either diagram to see more

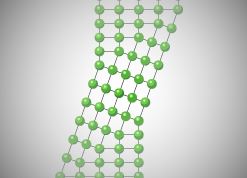

Slip

The animation shows how planes in a crystal structure

are moved by a dislocation passing through the material. The dislocation

itself is not shown. Many dislocations passing through a material leads

to irreversible plastic deformation. More information on dislocations

can be found here:

Dislocation TLP

Slip in an fcc crystal structure

Slip Plane

(111)

(111)

Slip direction

110 planes

Twinning

Deformation twinning is described by the twinning plane

and a twinning direction. Atoms move in the twinning direction by a

displacement, generating twinning shear. The twin's structure is a mirror

image of the parent structure about the twinning plane. The distance

moved is such that a fully coherent boundary is formed, that is each

atom is in the correct position related to the original system and the

twin lattice.

Twinning in an fcc crystal structure

Twinning Plane

(111)

(111)

Twinning direction

(112)

(112)

110 plane

Lattice points

Arrows

Arrows

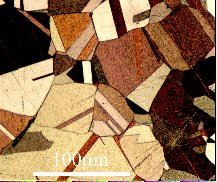

The shape of the twin is governed by the elastic strain

which developes as it grows within the parent grain. The twin grows

in a thin, sharply pointed plate as this minimises the elastic strain

energy producing a lenticular shaped twin. This lenticular shape differs

from annealing twins which form parallel sided twins to minimise interfacial

energy.

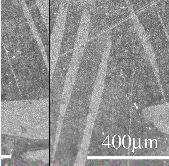

Deformation twins

Annealing twins

Sample of cold worked Zn showing deformation twinning

as an alternative to dislocation motion. Twinning is commonly observed

in structures of low crystallographic symmetry (eg. insufficient number

of independant slip systems) such as hcp metals like Zn. (Micrograph

Library sample 41)

Sample of Brass (Cu-30wt% Zn) showing annealing twins

produced as a result of recrystalisation and grain growth. Recrystallisation

(at high temperatures) allows sufficiant time for a diffusional rearrangement

of the atoms to form twins with parallel sides (Micrograph Library sample

430)