Water's effect on the mechanical behaviour of wood

The mass of water in a freshly felled tree is 60 to 200% of the dry mass of the tree. In dried out timber there is only roughly 10 weight percent water content. However timbers tend to achieve equilibrium with the surrounding air, settling to a moisture content of 22 to 23% in moist, water-saturated air. The effect of water on wood must therefore be considered. Combining and repeating the previous two experiments with the three-point bending equipment can help to demonstrate the effect. Some wood samples are soaked in water for 24 hours. This should ensure that they have a similar level of water content as green (newly felled) timber. The deflections of the wood samples are noted as the mass on the pan is increased in 100 g increments up to 600 g in order to calculate the Young’s modulus of the wood. The mass is then increased further until the failure load is reached. At this point the failure load and maximum displacement of the beam centre are noted. This should allow a measurement of the strength of the wet wood samples.

Video clip showing a three-point bend test to measure the deflection and failure load of a wet balsa sample

The stiffness and strength of the wet samples are worked out using the methods shown previously. By following this method and repeating for three samples of balsa, Scots pine and greenheart the following results were obtained:

|

Greenheart |

Scots pine |

Balsa |

Stiffness (GPa) |

16.1±1.7 |

6.0±0.7 |

2.2±0.7 |

Strength (MPa) |

112±3 |

47±4 |

11±3 |

Evidently increasing the water content of wood by soaking wood samples in this way lowers the stiffness and strength of the wood. When dry timber has its water content increased to the levels found in green timber, the cell walls fill with water. This causes the cell walls to expand and a dimensional change occurs. Water’s presence dramatically softens the cell walls. The hydrogen bonds between different polymer chains in the crystalline cellulose microfibrils can break. Hydrogen bonds form with water instead, as it is a small, polar molecule and so can get in between the polymer chains. Stronger hydrogen bonds are formed between cellulose and water than between cellulose and cellulose, making hydrogen bonding with water more favourable. This softens the cellulose microfibrils as they are no longer so strongly bonded to each other, making it easier to untangle and hence stretch the fibres. This leads to a decrease in the stiffness of wood.

As water is expanding the cell wall, there are also fewer cellulose microfibrils per unit area. Hence the strength of the wood decreases as, for a given applied stress, the load per fibre is greater. This makes the fibres more likely to break, leading to a crack in the wood sample, causing earlier sample failure.

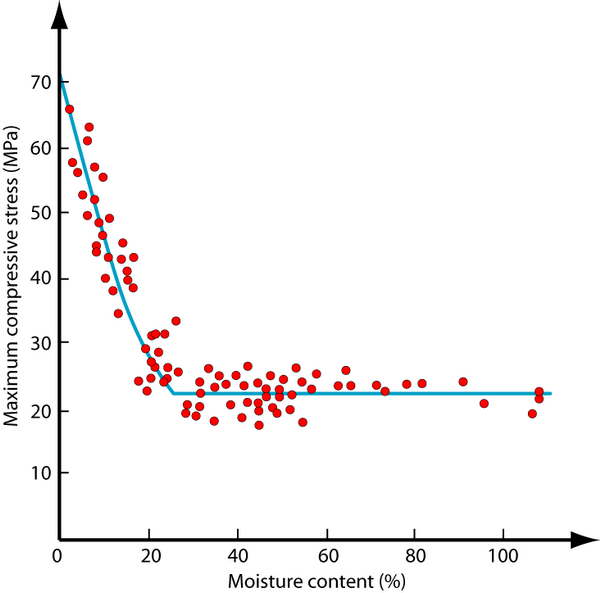

The graph below shows how the compressive strength of a sample of Scots pine changes as the water content increases. Under compression, there is a very marked weakening effect as water reduces the bonding between fibres, making cell walls easier to buckle.

Longitudinal compressive strength of timber as a function of its moisture content [1].