Stiffness of wood

The stiffness of wood can be measured using a simple three-point bend test as shown below:

Three-point bend test set-up

The width (w) and height (h) of wood samples are measured, and the specimens are placed in a three-point bend testing apparatus with the height of the wood oriented vertically in the apparatus. The distance (L) between the two supports is also measured. The deflection of the middle of the beam, as a function of load on the pan of the apparatus, is measured to calculate the stiffness. As the elastic properties of wood are being tested it is important to ensure that the sample does not become permanently deformed. To achieve this, the mass on the pan is increased stepwise in 100 g increments, ensuring that the deflection remains less than 3 mm, until a total mass of 600 g is reached. No load is added until the deflection caused by the previous load added has stabilised, and the equipment is not jogged or tapped, as these actions affect the results recorded.

Video of three-point bend test for Scots pine

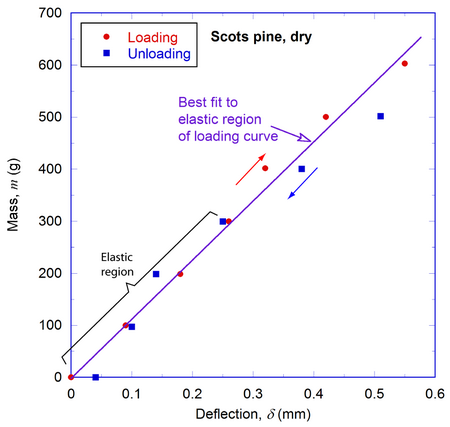

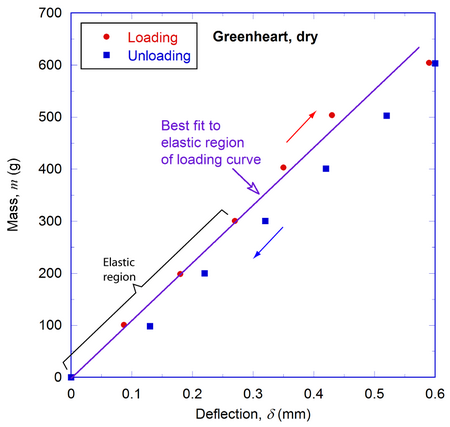

The resulting load (m) – displacement (d) curves on loading and unloading for (a) balsa, (b) Scots pine and (c) greenheart are shown below:

(a)

(a)

(b)

(b)

(c)

(c)

Using the equation for the deflection of a material under symmetric three-point bending:

\[\delta = \frac{{mg{L^3}}}{{48EI}}\]

The Young’s modulus for each sample is calculated from:

\[E = \frac{{g{L^3}}}{{48I}}\frac{m}{\delta }\]

Therefore from the graphs, the gradient is \(\frac{m}{\delta }\) and the other values have been measured as in this case \(I = \frac{{w{h^3}}}{{12}}\), so the Young’s modulus can be found. The results for balsa, Scots pine and greenheart are:

Greenheart |

Balsa |

Scots pine |

|

| E (GPa) | 16.4 ± 0.7 |

6.7 ± 0.3 |

13.5 ± 0.7 |

| Textbook values E (GPa) | 21 |

3.2 |

10 |

The textbook values represent a broader range of samples.

Clearly the definition of softwood and hardwood has little relation to the wood’s materials properties: the softwood Scots pine is much stiffer than the hardwood, balsa. This is mainly due to the ultra low density of balsa, as the stiffness (and also strength) of wood correlates with density.

The values of Young’s modulus show that wood is reasonably stiff. Wood is a composite material, and so to stretch the wood samples the cellulose microfibrils in the wood have to be stretched. The Young’s modulus of cellulose fibrils is 100 GPa, and that of lignin and hemicellulose averages to 6 GPa. Under axial loading, an equal strain condition applies and the Young’s modulus of the wood cell wall can be calculated as follows:

E wood cell wall = (1–f) Ecellulose + f Elignin-hemicellulose matrix

= 0.5 (100) + 0.5 (6) = 53 GPa

Clearly, the Young’s modulus of the cell wall is a lot higher than that of wood, as the cells and spaces in the wood filled by air or water also affect wood’s Young’s modulus, decreasing its value. However wood cell wall has measured values of Young’s modulus of 10 to 60 GPa, and so the composite model of the cell wall provides an accurate mechanical description of its behaviour.

The loading and unloading curves do not exactly coincide. This demonstrates that wood shows viscoelastic properties under deformation. Viscoelasticity is advantageous, not least because it dampens vibrations: in high winds damping of resonance protects the branches and trunk from excessive deflections associated with damage. A stiff material could also limit deflections, but at the expense of high stresses. Overall, it is preferable to be able to bend. The origins of wood’s viscoelastic behaviour lie in the lignin matrix. Lignin is an amorphous polymer, and its elastic regions respond instantly to the strain while the viscous regions respond more slowly. Due to this viscoelasticity, energy is dissipated in the wood on loading. On the graphs the area between the loading and unloading curves shows the elastic strain energy that is being stored in the wood. However the amount of energy is not high enough to cause problems. In living trees, in particular, the high water content of the wood inside the cells and extracellular matrix restricts a significant temperature rise, because of the high heat capacity of water.