Micrograph Library

Browse the libraryAdvanced searchSystemsCompositionsTechniquesKeywordsPhase diagramsHelpPreferencesAbout the micrograph libraryTerms of useContribute micrographs!FeedbackLinksCredits Print this page

Micrograph 593 and full record

- Micrograph no

- 593

- Brief description

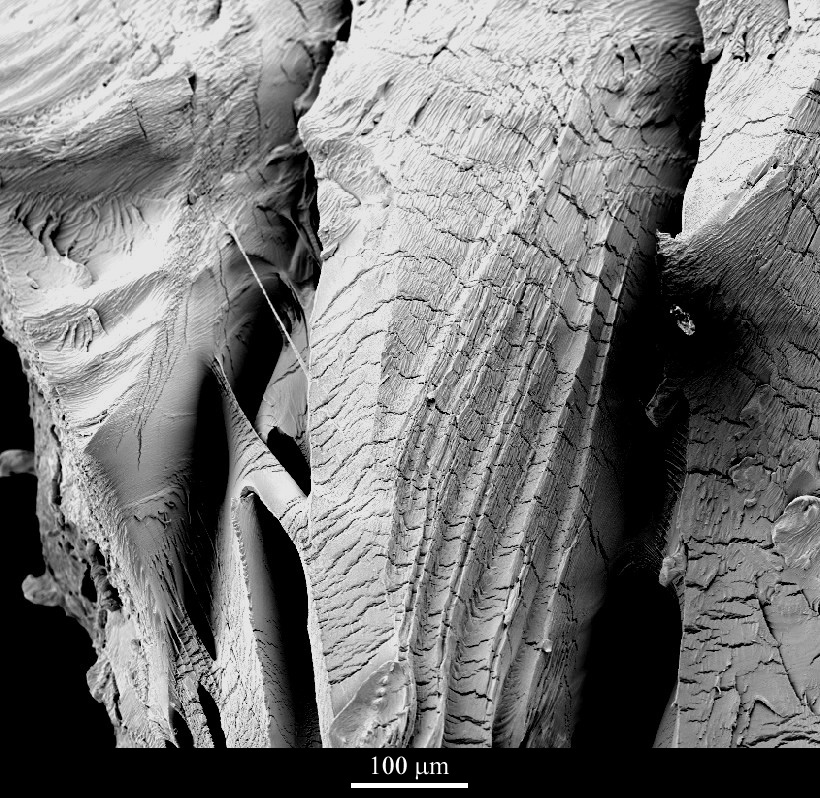

- Ductile tearing near a fracture surface in polycarbonate

- Keywords

- craze

, ductile

, ductile  , ductile tearing, fibril

, ductile tearing, fibril  , fracture

, fracture  , polycarbonate (PC), polymer

, polycarbonate (PC), polymer

- Categories

- Fracture, Polymer

- System

- Polycarbonate (PC)

- Composition

- Not specified

- Standard codes

- Reaction

- Processing

- Applications

- Polycarbonate is a clear and relatively tough plastic used to make shatterproof windows, lenses and even helmets. It is also used to make compact discs.

- Sample preparation

- To induce crazing and fracture in polycarbonate, acetone is used. This results in the otherwise tough material becoming very brittle

- Technique

- Scanning electron microscopy (SEM)

- Length bar

- 100 μm

- Further information

- The fracture surface is dominated by ductile tearing, and also shows linear voids with fine transverse filaments. These are the remnants of crazes which act both as a precursor to cracking and as a toughening mechanism. In some areas, more angular brittle fracture surfaces are also apparent. The fine-scale ridging of the surface, parallel to the principal stress direction (which is approximately vertical) morphology is the result of fibrous crystals being induced by cold-drawing.

- Contributor

- J A Curran

- Organisation

- Department of Materials Science and Metallurgy, University of Cambridge

- Date

- 03/10/02

- Licence for re-use

Attribution-NonCommercial-ShareAlike 4.0 International

Attribution-NonCommercial-ShareAlike 4.0 International- Related micrographs

View image alone .. in a new window

Help is available on downloading images