Are stresses concentrated at a crack tip?

A small crack could be made to grow into the material, by gently tapping a razor blade onto the edge of a piece of polycarbonate. This can introduce internal stresses, so the sample was annealed at 140 °C for 45 minutes to reduce them as much as possible.

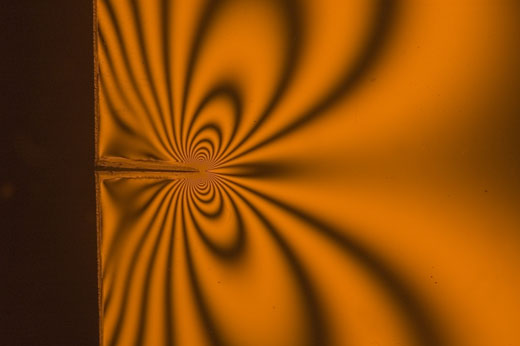

The sample was loaded so that the crack was perpendicular to the loading direction and viewed under polarised light.

The dark bands show contours of constant difference between the two principal stresses. Away from the crack, zero stress can be assumed parallel to the crack direction. This allows us to calculate a ‘far field’ stress.

We know the stress-optical coefficient for polycarbonate, and the thickness of the sample, so the stress difference for each successive contour can be calculated at just over 2.5 MPa.

The contours become closer together near the crack tip – showing that the stress increases as you get nearer the crack tip. Some more images, including white light and variable crack length pictures can be viewed here.

7.25 mm crack in polycarbonate under monochromatic light