Jominy end quench test

The test sample is a cylinder with a length of 102 mm (4 inches) and a diameter of 25.4 mm (1 inch).

Jominy test specimen

The steel sample is normalised to eliminate differences in microstructure due to previous forging, and then austenitised. This is usually at a temperature of 800 to 900°C. The test sample is quickly transferred to the test machine, where it is held vertically and sprayed with a controlled flow of water onto one end of the sample. This cools the specimen from one end, simulating the effect of quenching a larger steel component in water.

Jominy test machine

The cooling rate varies along the length of the sample from very rapid at the quenched end, to rates equivalent to air cooling at the other end.

The round specimen is then ground flat along its length to a depth of 0.38 mm (15 thousandths of an inch) to remove decarburised material. The hardness is measured at intervals from the quenched end. The interval is typically 1.5 mm for alloy steels and 0.75 mm for carbon steels.

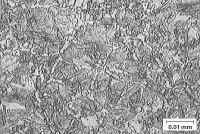

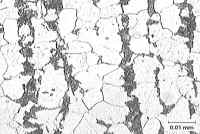

High hardness occurs where high volume fractions of martensite develop. Lower hardness indicates transformation to bainite or ferrite/pearlite microstructures.

|

|

|

Martensite |

Ferrite/pearlite |

Jominy end quench hardness data for two steels of different hardenability can be seen in a later section of this TLP, with images of the microstructure variation along the length of the sample.

Similar tests have been developed in other countries, such as the SAC test, which uses a sample quenched from all sides by immersion in water. This is commonly used in the USA.