Re-use of this resource is governed by a Creative Commons

Attribution-

NonCommercial-ShareAlike 4.0 International

https://creativecommons.org/licenses/by-nc-sa/4.0/

NonCommercial-ShareAlike 4.0 International

https://creativecommons.org/licenses/by-nc-sa/4.0/

Vickers hardness test

Vickers hardness measures the material's resistance to localised plastic deformation, eg. wearing or indentation.

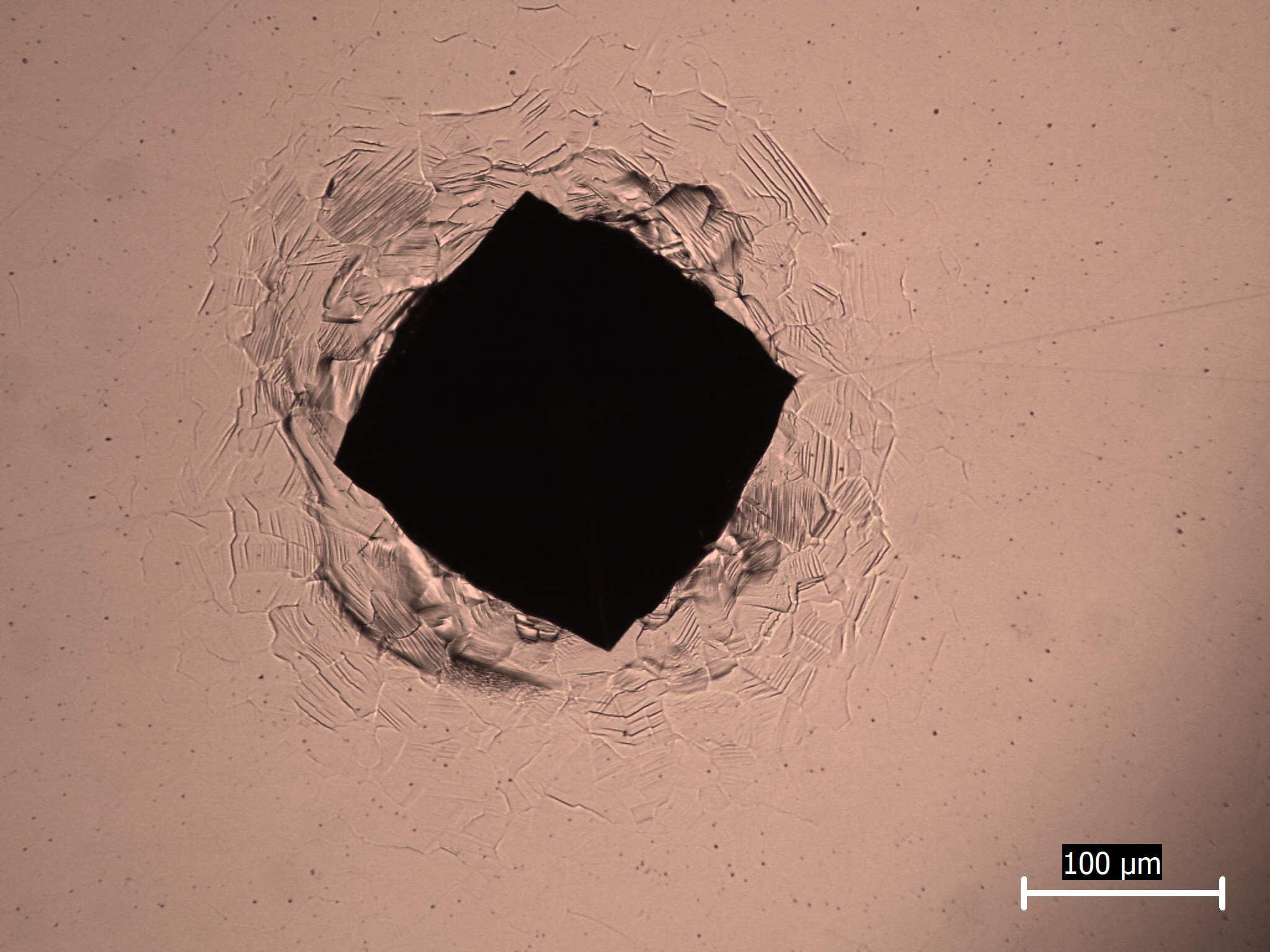

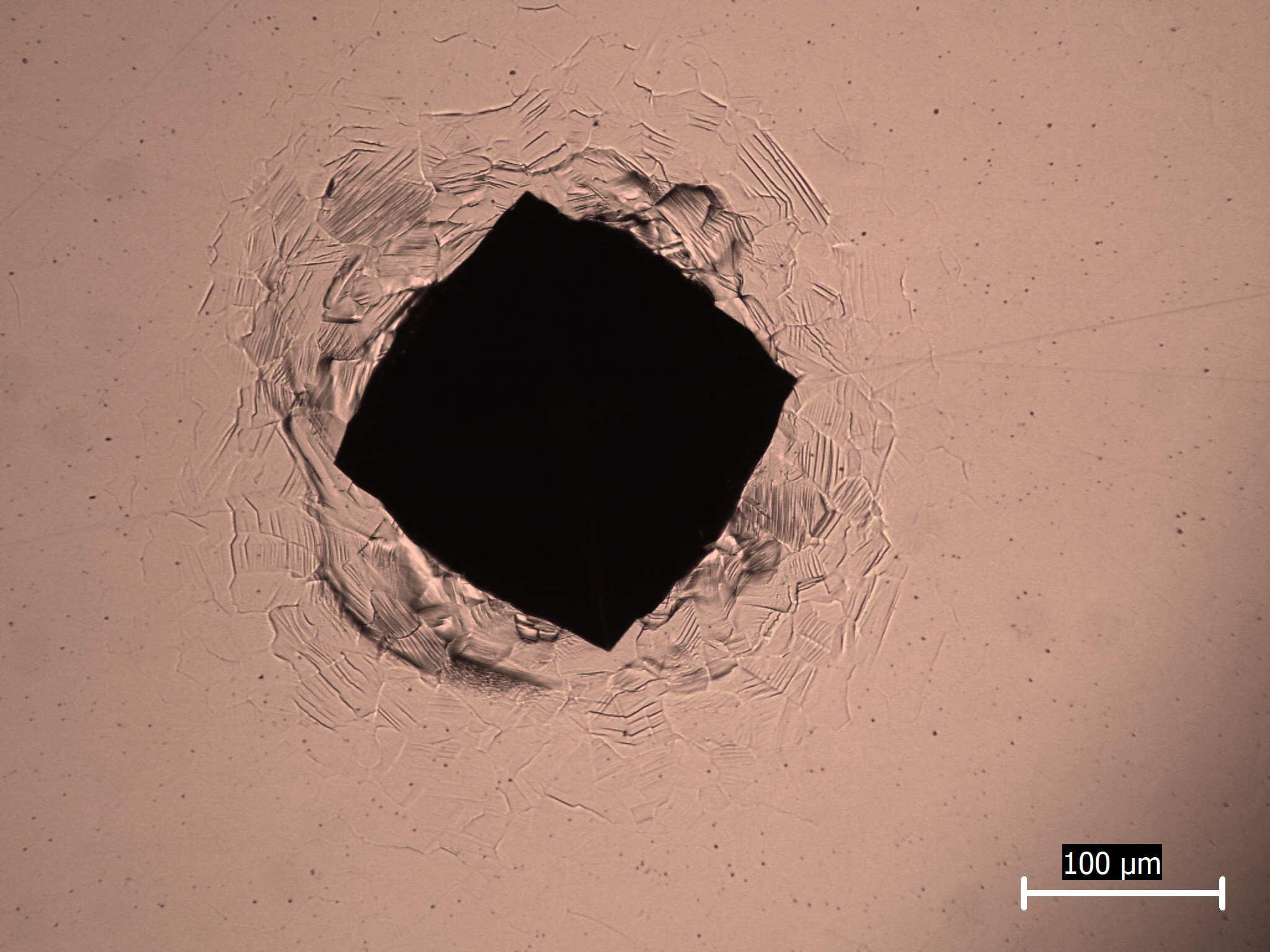

The sample is polished to give a shining and flat surface. On such a surface, a diamond indenter is loaded with a known test force F to give a square indent.

The test force F can be amended so that the size of the indent is large enough to cover several grains (consider grain boundaries) and not too large to be measured down the microscope.

The sample is polished to give a shining and flat surface. On such a surface, a diamond indenter is loaded with a known test force F to give a square indent.

The test force F can be amended so that the size of the indent is large enough to cover several grains (consider grain boundaries) and not too large to be measured down the microscope.

Materials with higher hardness usually requires a higher test force F.

Here, we use a of 3.0 kgf to test the hardness of copper.

Here, we use a of 3.0 kgf to test the hardness of copper.

Vickers hardness test

The indent is studied under a microscope.

the diagonal length of the indent D, using two glass slides connected to a micrometer. Make sure you do not the corner!

the diagonal length from the micrometer. Being aware of the magnification x10, the real length is therefore 10 times smaller than the reading below.

the diagonal length of the indent D, using two glass slides connected to a micrometer. Make sure you do not the corner!

the diagonal length from the micrometer. Being aware of the magnification x10, the real length is therefore 10 times smaller than the reading below.

Vickers hardness test

the lens, and the measurement.

Take the of two diagonal length.

Magnification is x10, so the is

hardness.

Vickers hardness test

Now try to test different materials yourself:

Fe-C alloy with lower carbon content.

Fe-C alloy with higher carbon content.

Cu-46 wt% Zn α-β brass.

Almost pure Al.

Almost pure Cu.

Press to compare the hardness of the metaliic materials above.

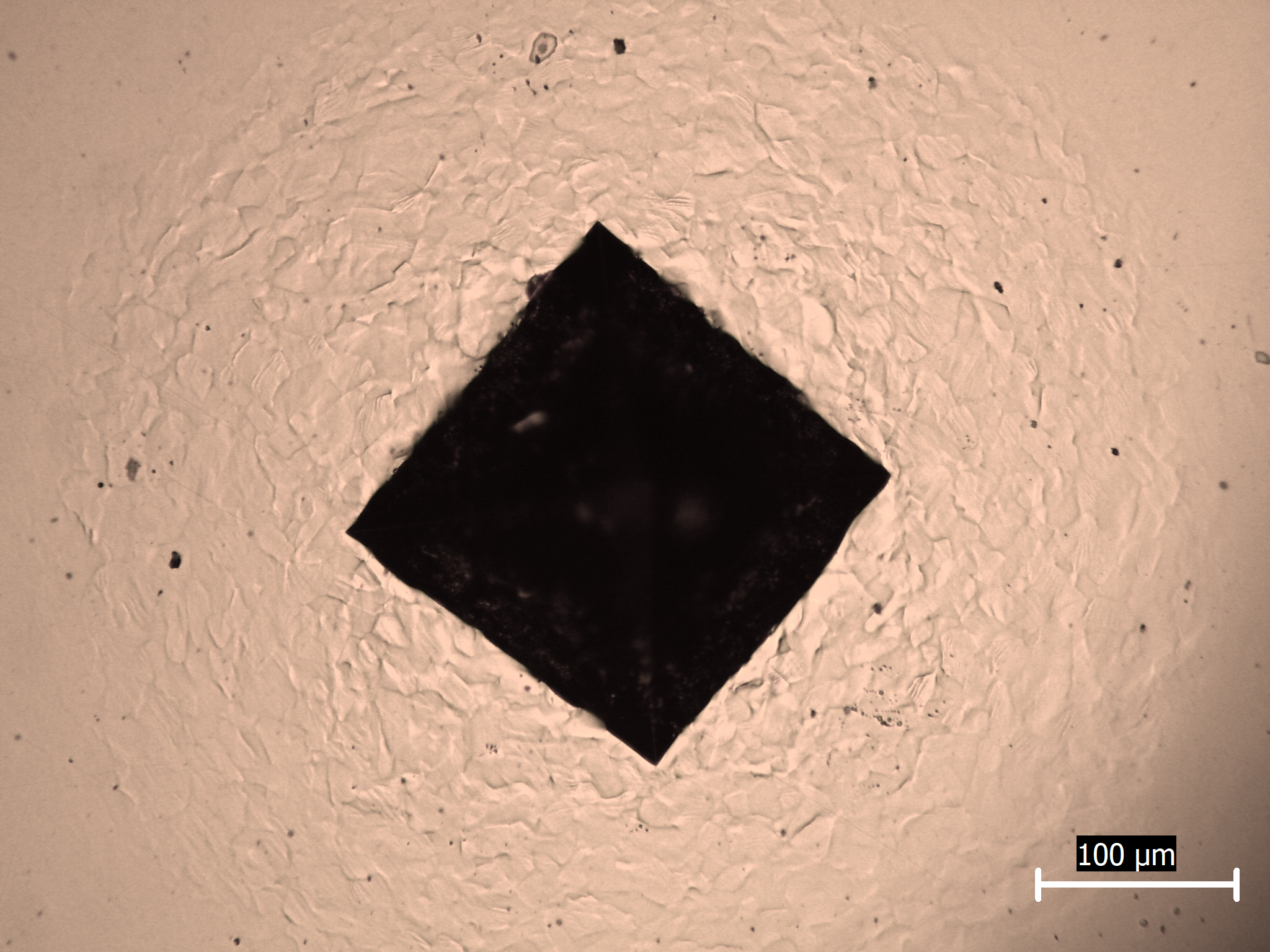

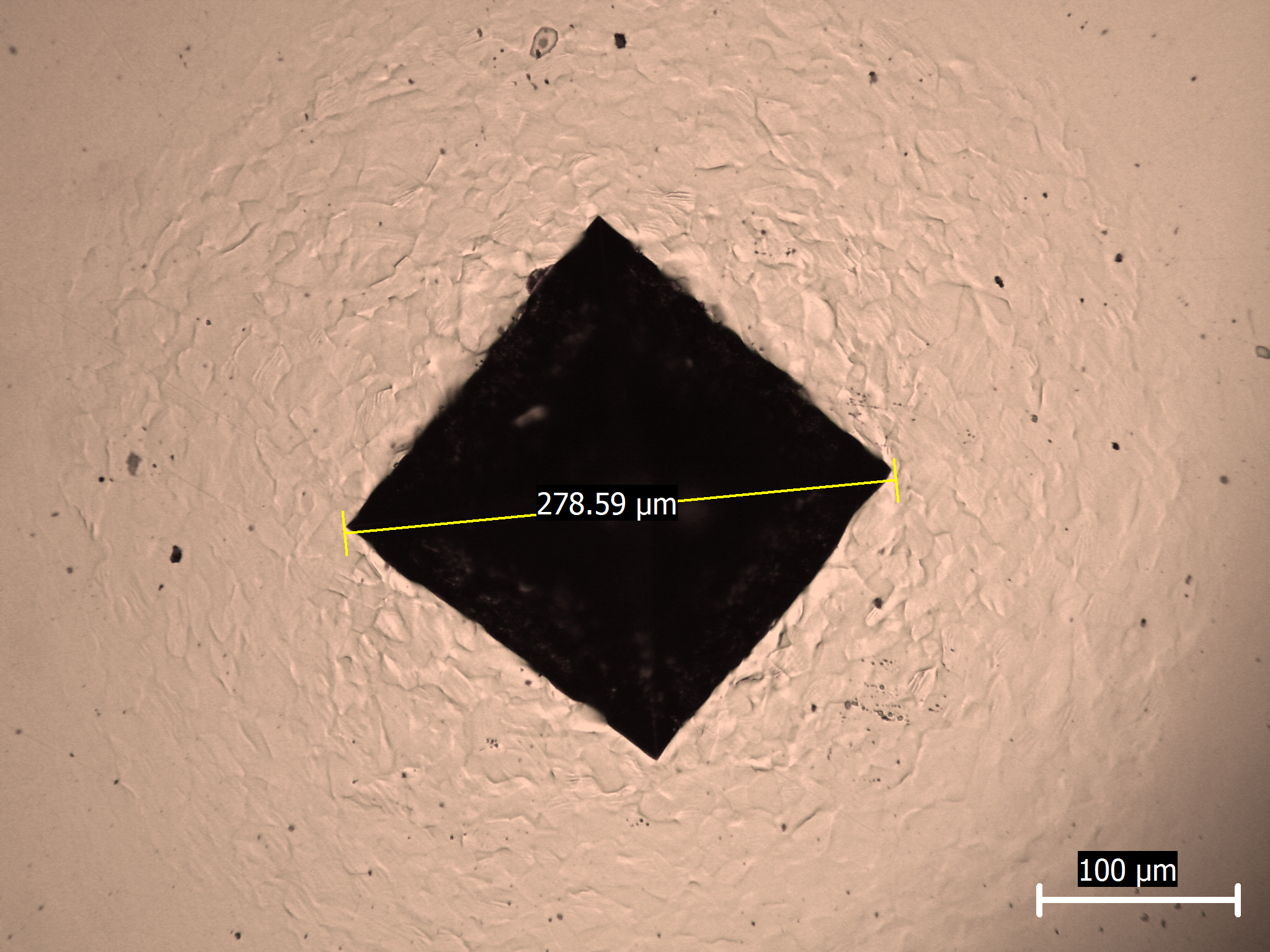

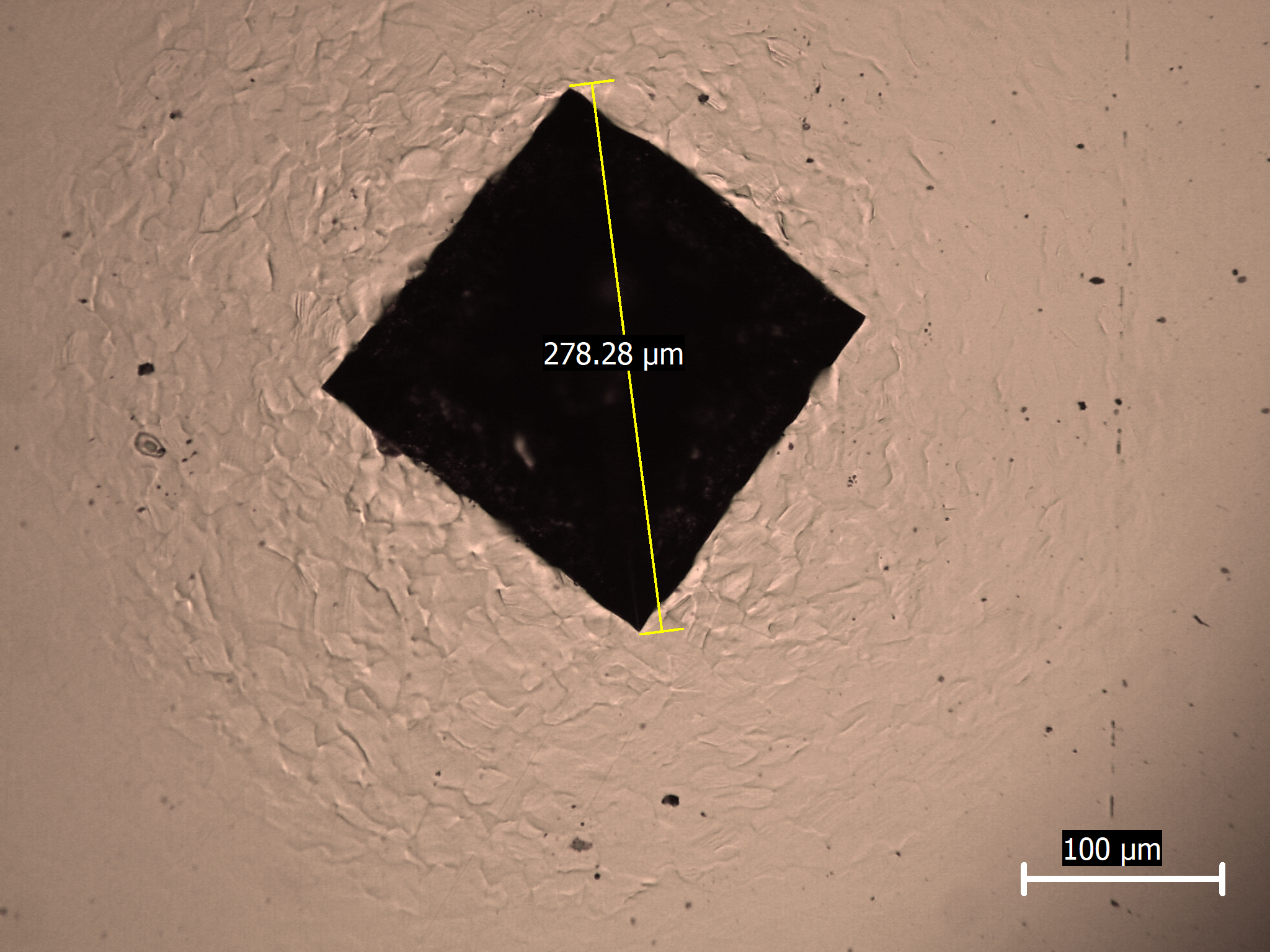

Vickers hardness test for mild steel

Vickers hardness test for mild steel

Measure the diagonal length of the indent using the slider below. Check your measurement by clicking "next".

Vickers hardness test for mild steel

The average diagonal length D = 278 μm = 0.278 mm

The test force F = 5.0 kgf

The hardness Hv = 1.854 F / D2 = 120 HV 5.0

Where "5.0" stands for the 5.0 kgf test force.

Click "next" to test other materials.

The test force F = 5.0 kgf

The hardness Hv = 1.854 F / D2 = 120 HV 5.0

Where "5.0" stands for the 5.0 kgf test force.

Click "next" to test other materials.

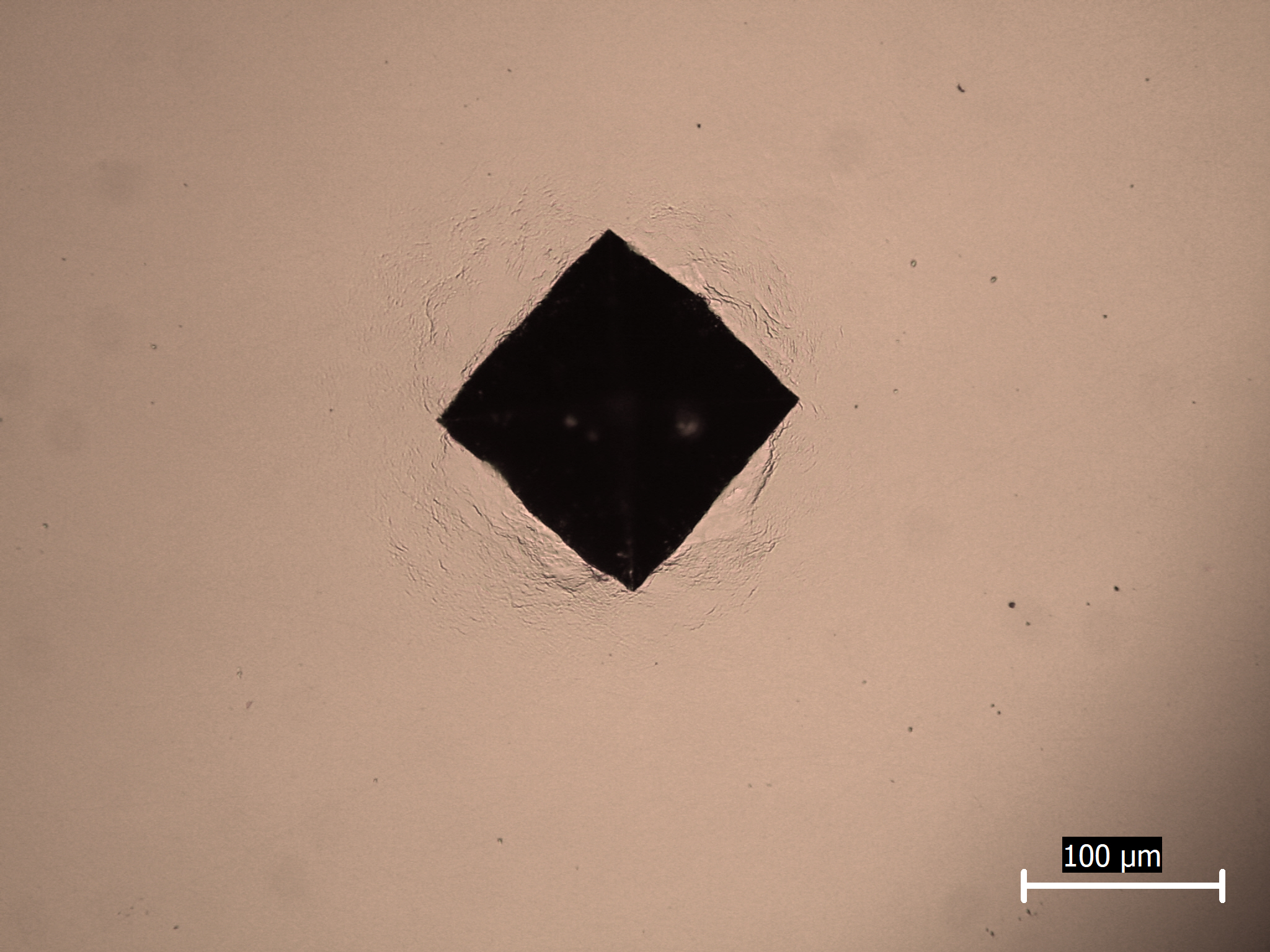

Vickers hardness test for silver steel

Vickers hardness test for silver steel

Measure the diagonal length of the indent using the slider below. Check your measurement by clicking "next".

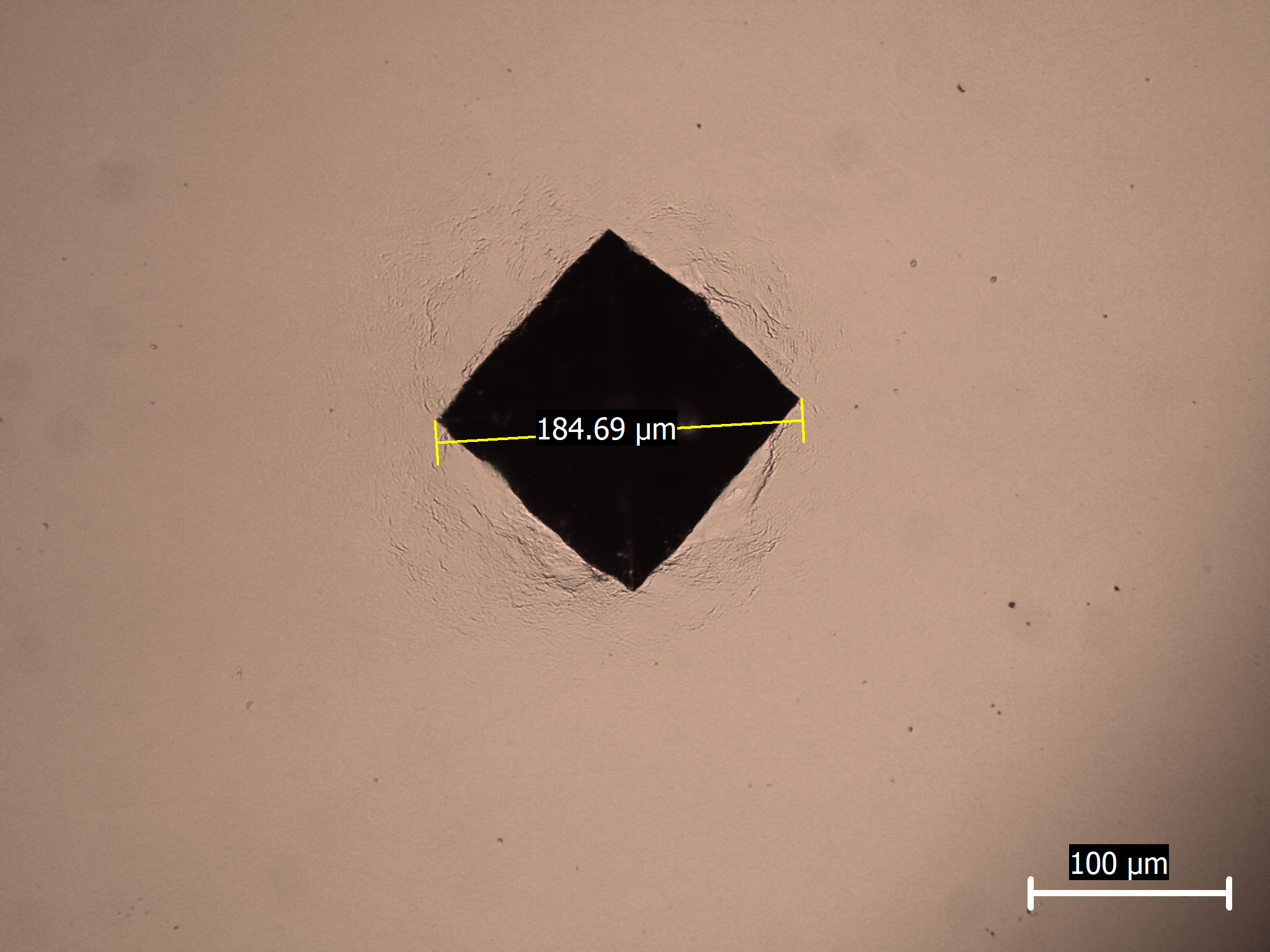

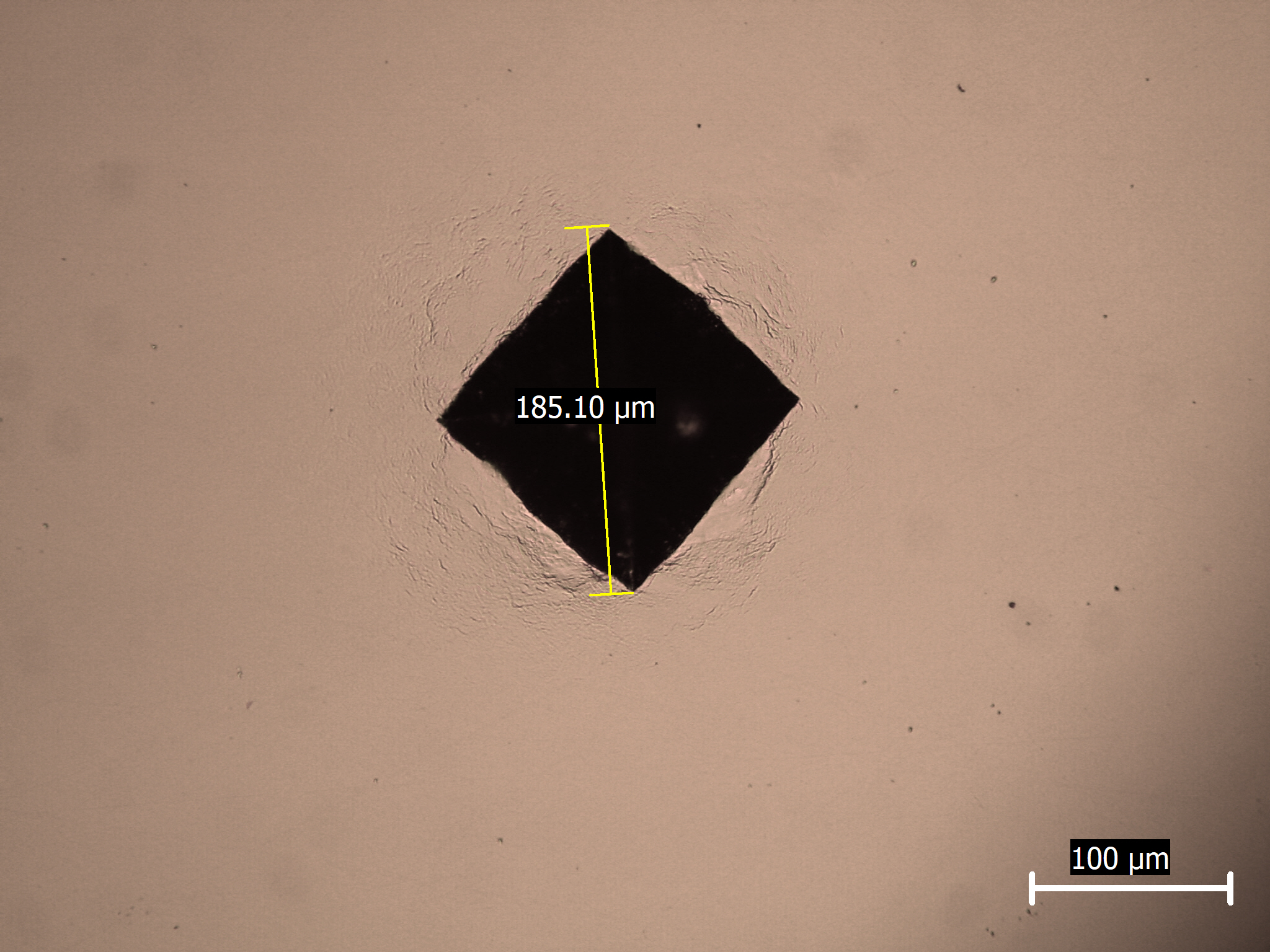

Vickers hardness test for silver steel

The average diagonal length D = 185 μm = 0.185 mm

The test force F = 5.0 kgf

The hardness Hv = 1.854 F / D2 = 270 HV 5.0

Where "5.0" stands for the 5.0 kgf test force.

Click "next" to test other materials.

The test force F = 5.0 kgf

The hardness Hv = 1.854 F / D2 = 270 HV 5.0

Where "5.0" stands for the 5.0 kgf test force.

Click "next" to test other materials.

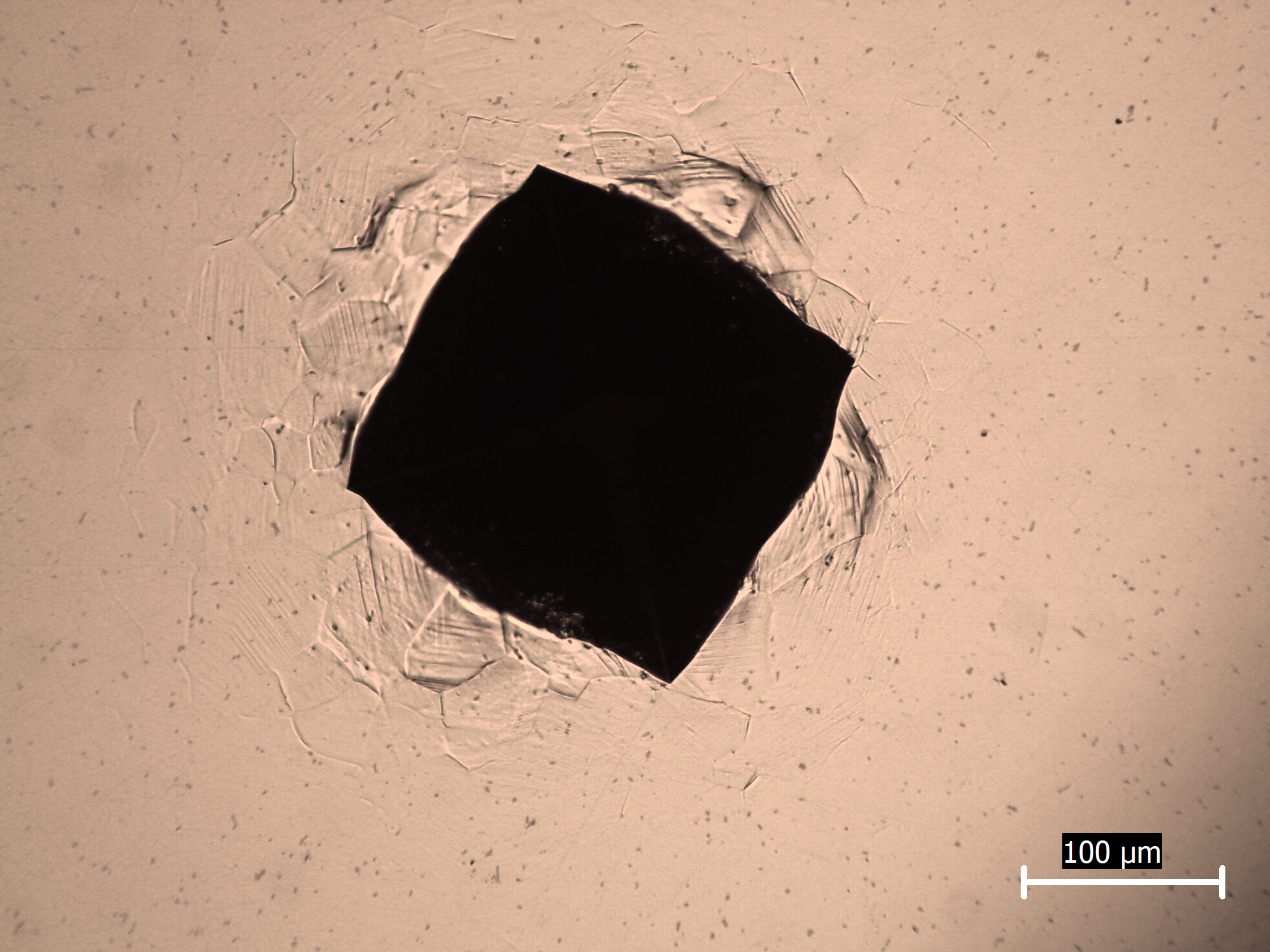

Vickers hardness test for brass

Vickers hardness test for brass

Measure the diagonal length of the indent using the slider below. Check your measurement by clicking "next".

Vickers hardness test for brass

The average diagonal length D = 255 μm = 0.255 mm

The test force F = 5.0 kgf

The hardness Hv = 1.854 F / D2 = 142 HV 5.0

Where "5.0" stands for the 5.0 kgf test force.

Click "next" to test other materials.

The test force F = 5.0 kgf

The hardness Hv = 1.854 F / D2 = 142 HV 5.0

Where "5.0" stands for the 5.0 kgf test force.

Click "next" to test other materials.

Vickers hardness test for aluminium

Vickers hardness test for aluminium

Measure the diagonal length of the indent using the slider below. Check your measurement by clicking "next".

Vickers hardness test for aluminium

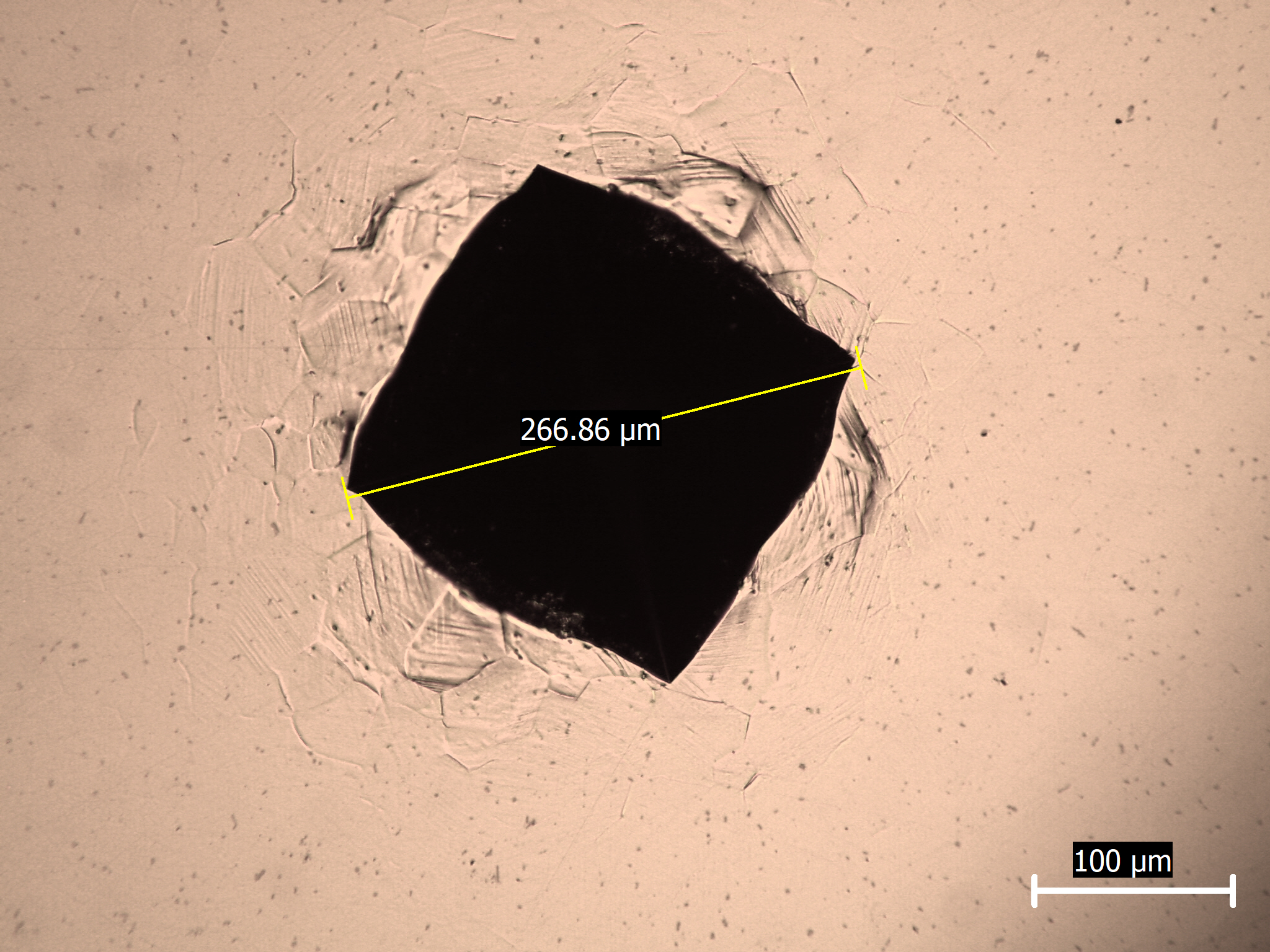

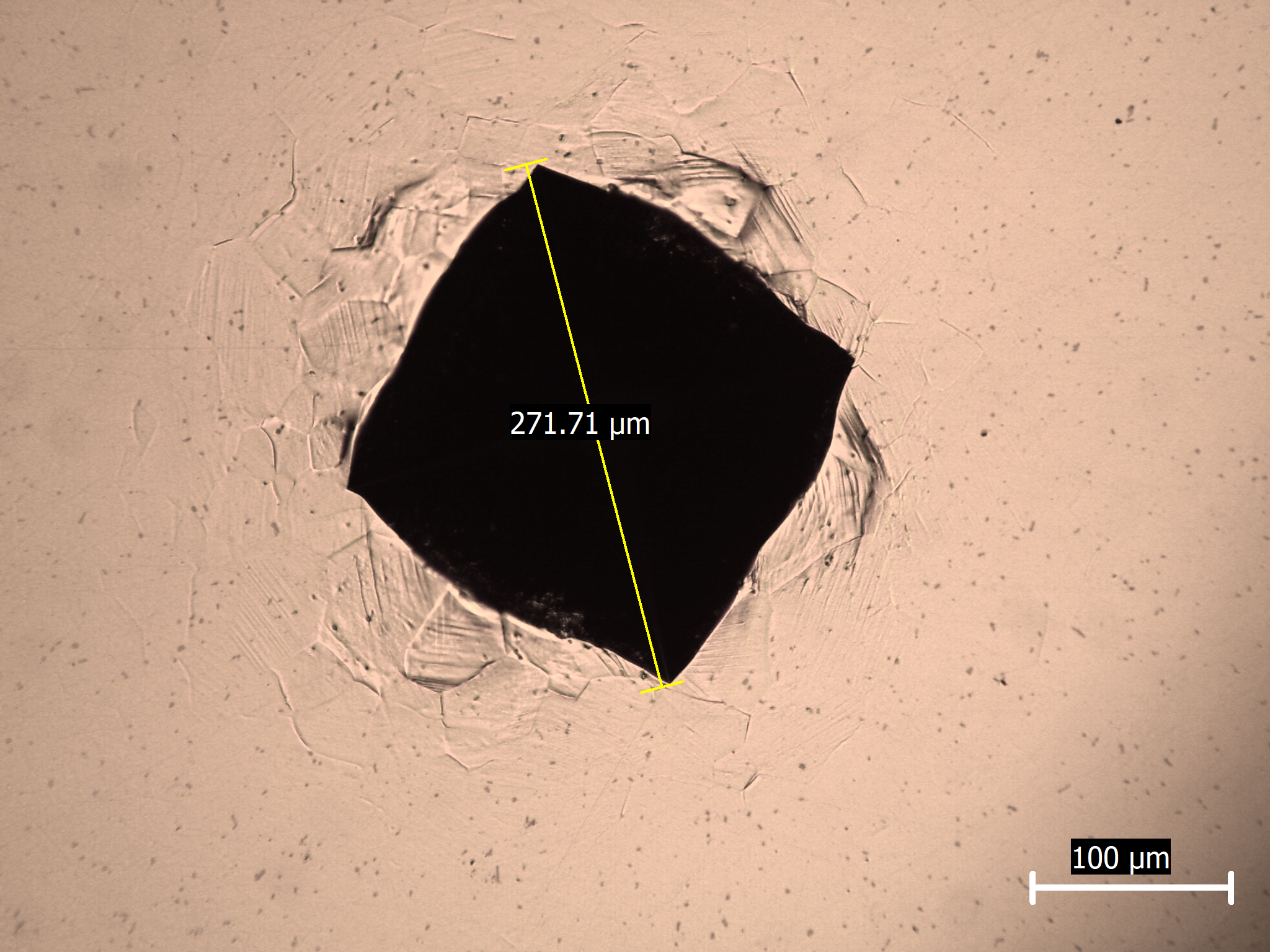

The average diagonal length D = 269 μm = 0.269 mm

The test force F = 3.0 kgf

The hardness Hv = 1.854 F / D2 = 77 HV 3.0

Where "3.0" stands for the 3.0 kgf test force.

Click "next" to test other materials.

The test force F = 3.0 kgf

The hardness Hv = 1.854 F / D2 = 77 HV 3.0

Where "3.0" stands for the 3.0 kgf test force.

Click "next" to test other materials.

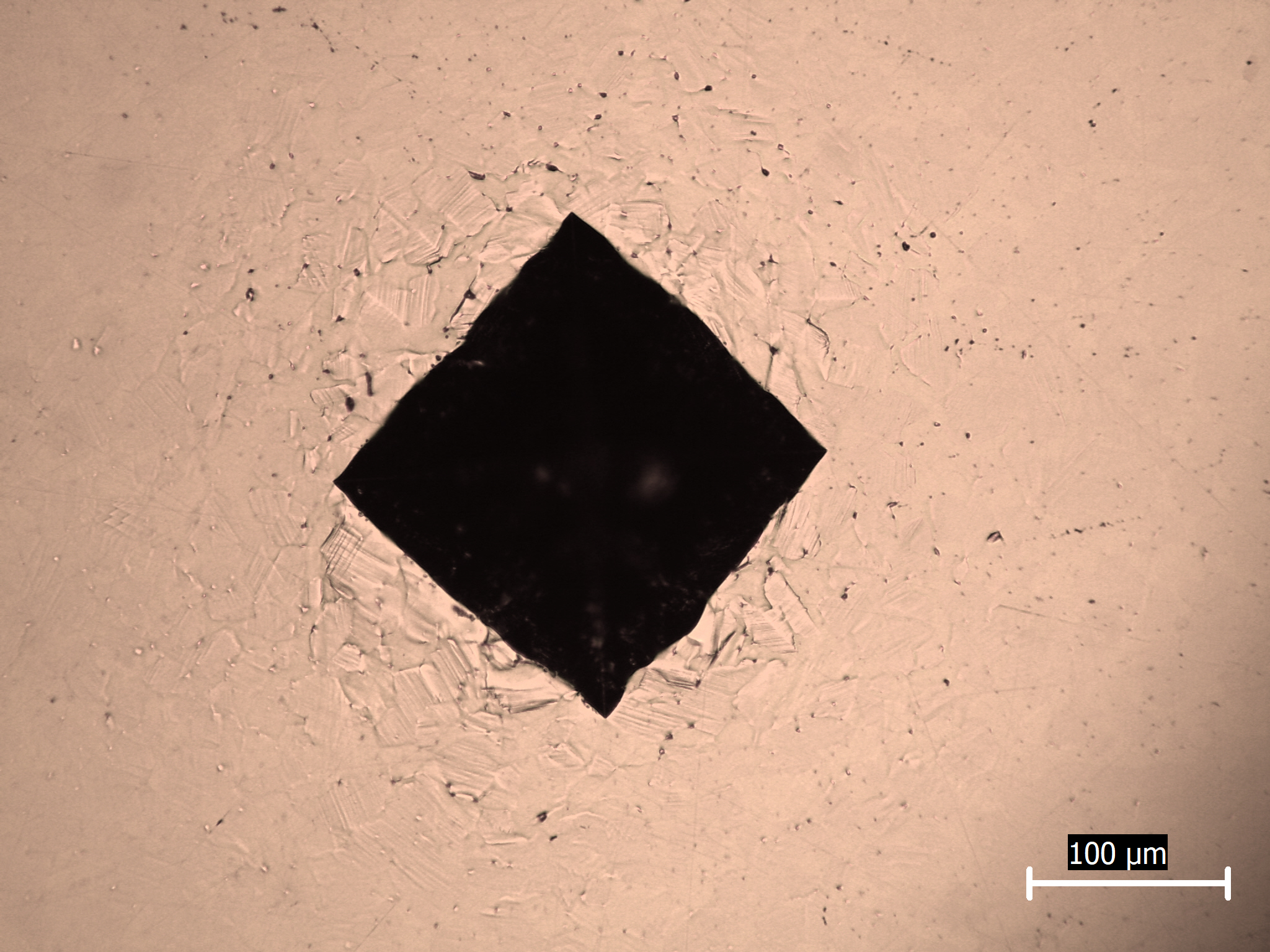

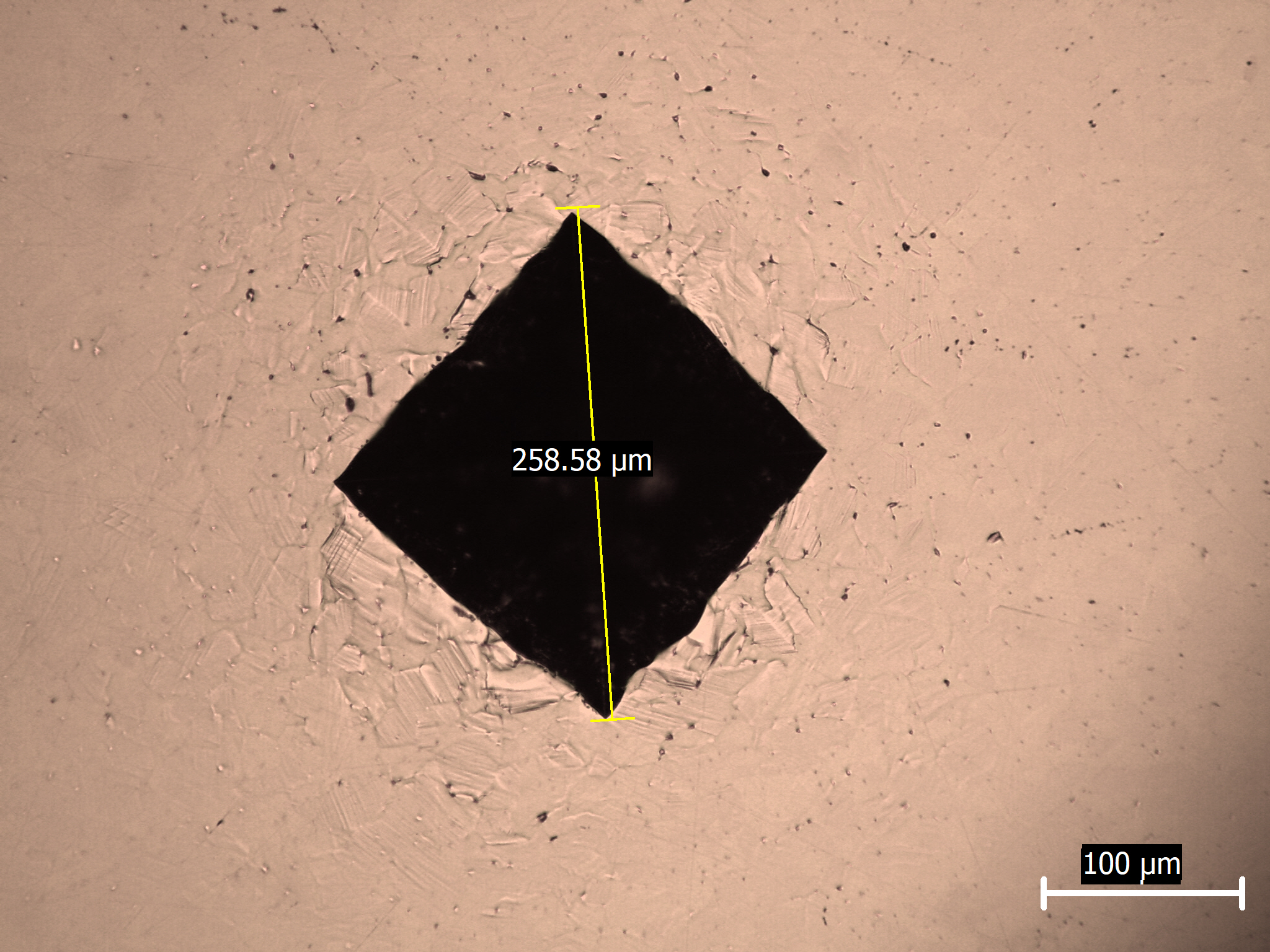

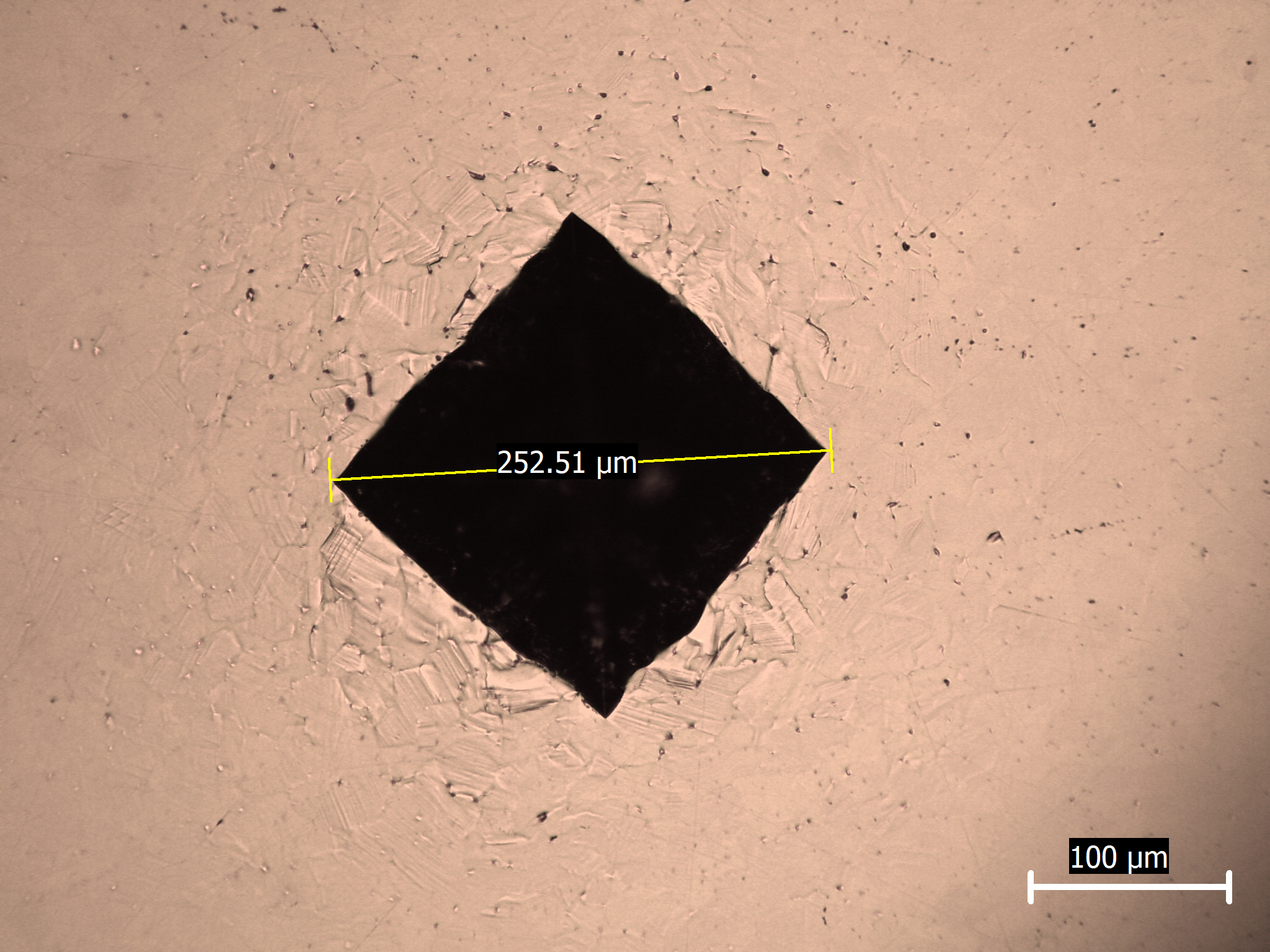

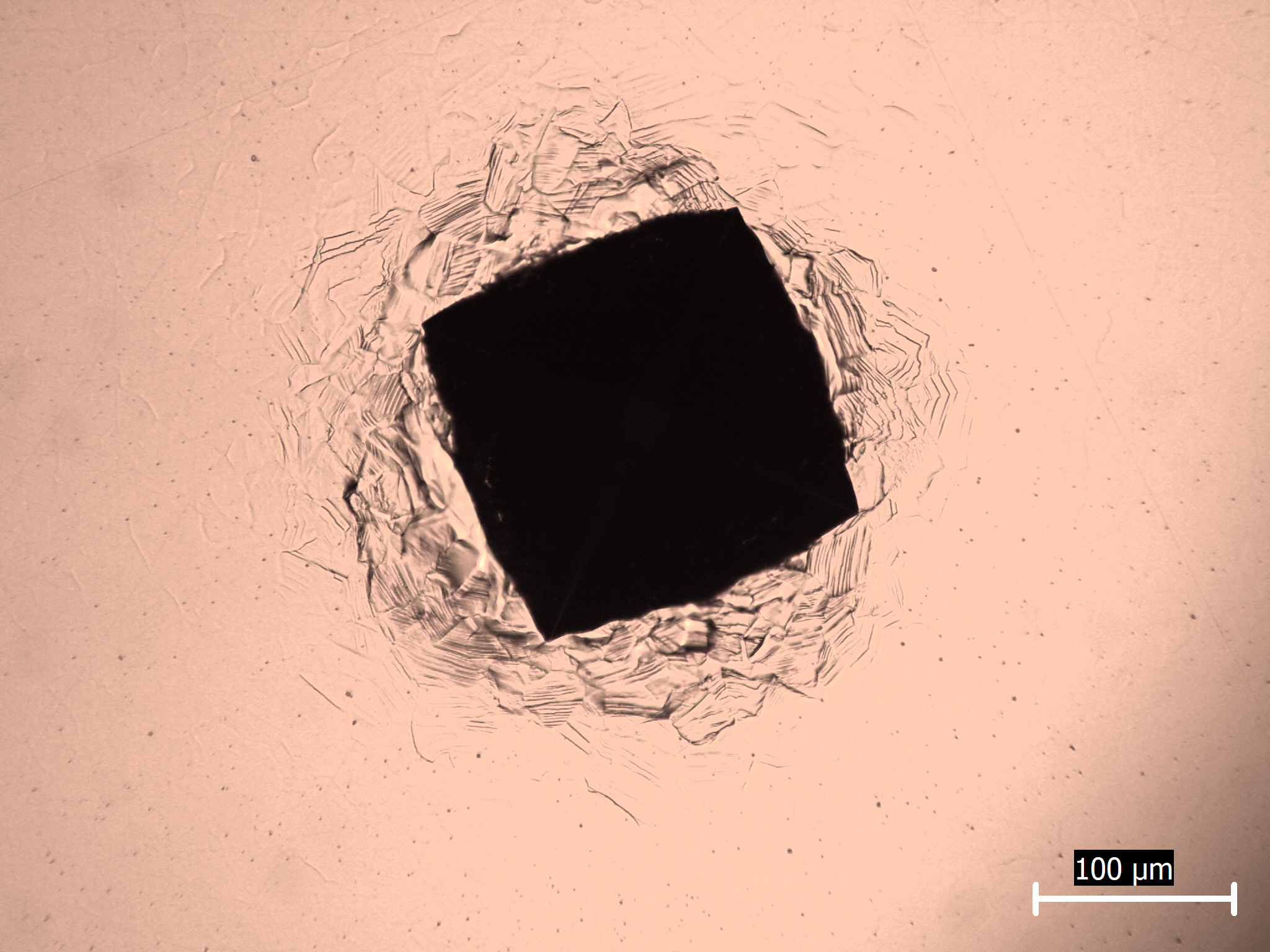

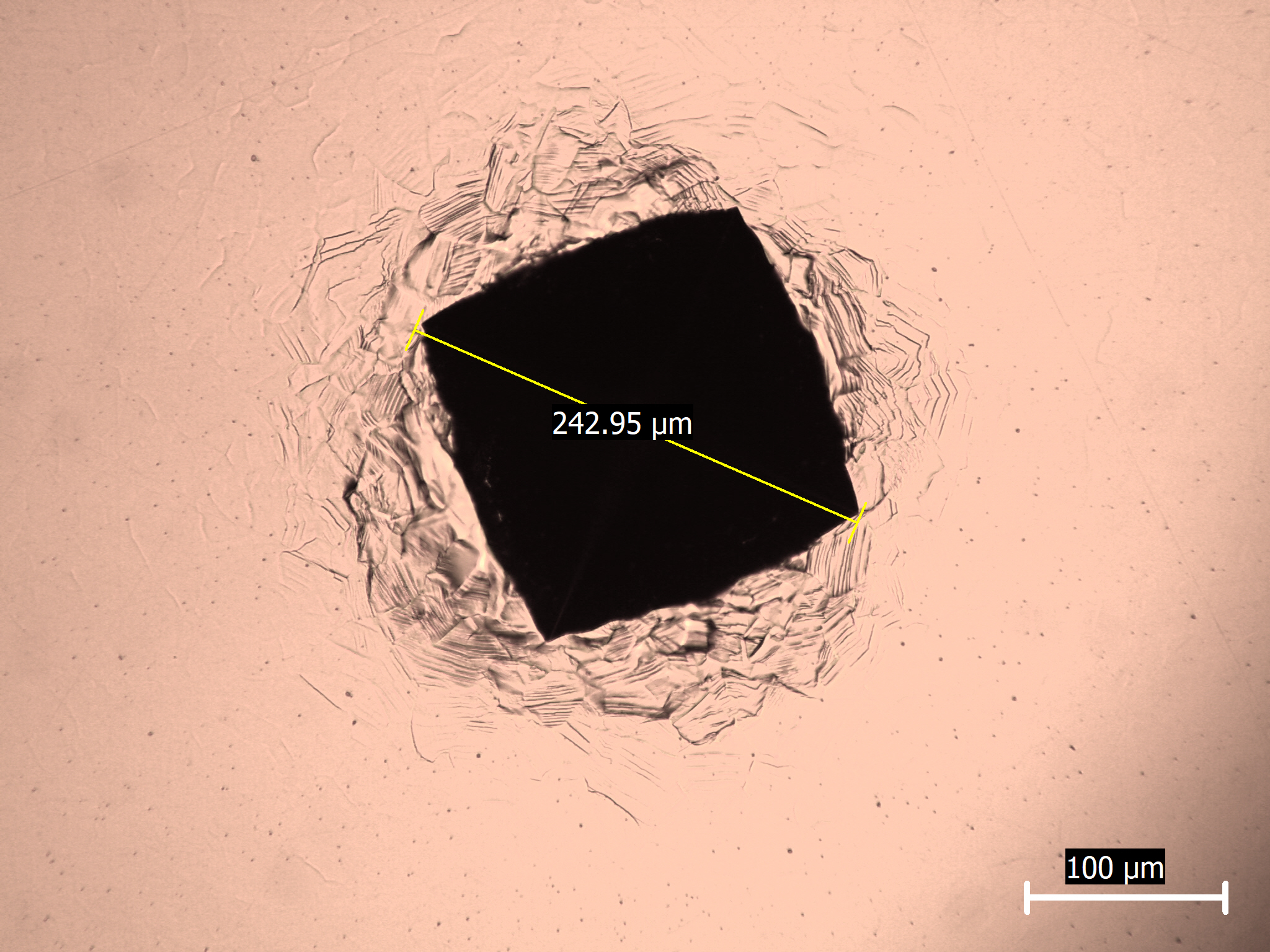

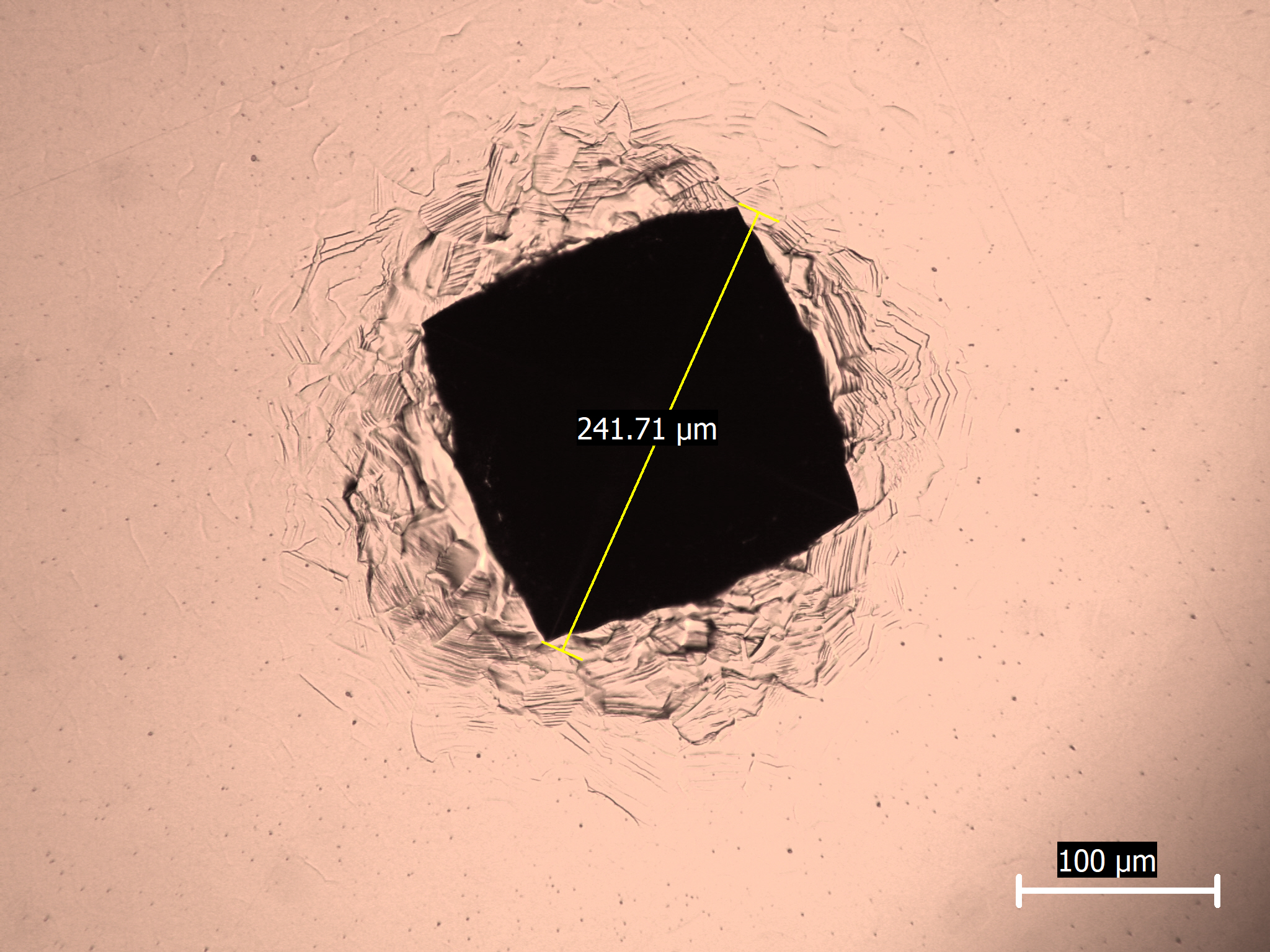

Vickers hardness test for copper

Vickers hardness test for copper

Vickers hardness test for copper

The average diagonal length D = 242 μm = 0.242 mm

The test force F = 3.0 kgf

The hardness Hv = 1.854 F / D2 = 94 HV 3.0

Where "3.0" stands for the 3.0 kgf test force.

Click "next" to test other materials.

The test force F = 3.0 kgf

The hardness Hv = 1.854 F / D2 = 94 HV 3.0

Where "3.0" stands for the 3.0 kgf test force.

Click "next" to test other materials.

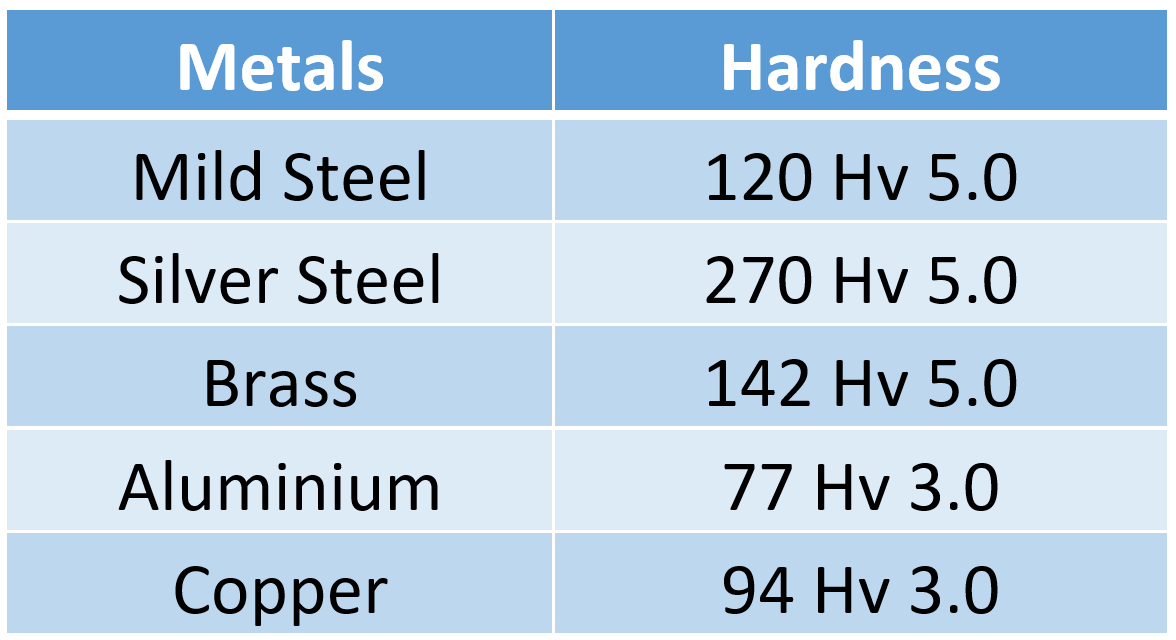

Metals under Vickers hardness test

"5.0" and "3.0" stand for 5 kfg and 3 kgf test force respectively.

Note a smaller test force is used for aluminium and copper so that the indent will not be too large to be measured.

Steel and brass have a higher hardness than aluminium and copper. Steel and brass are therefore more resistant to wearing compared to aluminum and copper.

Note a smaller test force is used for aluminium and copper so that the indent will not be too large to be measured.

Steel and brass have a higher hardness than aluminium and copper. Steel and brass are therefore more resistant to wearing compared to aluminum and copper.