Introduction To Deformation Processes (all content)

Note: DoITPoMS Teaching and Learning Packages are intended to be used interactively at a computer! This print-friendly version of the TLP is provided for convenience, but does not display all the content of the TLP. For example, any video clips and answers to questions are missing. The formatting (page breaks, etc) of the printed version is unpredictable and highly dependent on your browser.

Contents

Aims

On completion of this TLP you should:

- Be aware of major deformation processes and the ways in which they are used to form metallic objects:

- Rolling

- Extrusion

- Forging

- Drawing

- Appreciate the advantages and disadvantages of each.

- Understand the reasons for selecting a process for a particular shape of end product.

Before you start

A basic understanding of plastic deformation (including work hardening) is assumed and can be found in the Mechanical Testing of Metals TLP.

Introduction

A forming operation is one in which the shape of a metal sample is altered by plastic deformation. Forming processes include stamping, rolling, extrusion and forging, where deformation is induced by external compressive forces or stresses exceeding the yield stress of the material. Drawing is a fundamentally different process in that the external forces are tensile in nature and hence the ultimate tensile strength of the material cannot be exceeded.

Metals or alloys used in forming processes require a moderate level of ductility to enable plastic deformation with no fracture.

Some formed articles

Forming can be divided into two categories:

![]()

Hot Working

Hot ingots from Phase Transition Group web page

DoITPoMS standard terms of use

Deformation is carried out at a temperature high enough for fast recrystallisation to occur. A crude estimate for a hot working temperature T for a particular metal or alloy is that it must be greater than 0.6Tm where Tm is the melting point in degrees Kelvin. This lower bound for the hot working temperature varies for different metals, depending on factors such as purity and solute content. Thus, a highly pure metal will undergo recovery and recrystallisation at a particular hot working temperature more readily than an alloyed metal.

Deformation energy requirements for hot working are less than that of cold working. At hot working temperatures, a metal remains ductile through dynamic reforming of its grain structure, so repeated, large deformations are possible. The strain rates of many metal-working processes are so high that there is insufficient time for the metal to recrystallise as it deforms. However, recovery and recrystallisation do occur in the time period between repeated hot working operations.

Hot working achieves both the mechanical purpose of obtaining the desired shape and also the purpose of improving the physical properties of the material by destroying its original cast structure. The porous cast structure, often with a low mechanical strength, is converted to a wrought structure with finer grains, enhanced ductility and reduced porosity. Depending on the final hot working temperature, an annealed microstructure can be obtained.

At elevated temperatures, most metals experience some surface oxidation, which results in a poor surface finish as well as a loss of material. Processing in an inert atmosphere is possible, but it is very expensive and is usually avoided unless the metal is very reactive.

![]()

Cold Working

This is the term for processes that are performed at room temperature (or up to about 200°C for some metals). Cold working leads to anisotropy and increased stiffness and strength in a metal. There is a corresponding decrease in ductility and malleability as the metal strain hardens. Advantages over hot working include a better quality surface finish, closer dimensional control of the final article and improved mechanical properties.

Cold working processes can be divided into two broad classes:

1. Those in which cold working is carried out for the purpose of shaping the article only.

- Here, any strain hardening effects are not desired and may have to be removed by annealing both between the various stages of plastic shaping as well as after the final cold working shaping operation.

2. Those in which the object of cold rolling is not only to obtain the required shape but also to strain harden and strengthen the metal.

- Plastic deformation must not be carried beyond a certain point or brittle fracture is likely to result. In order to avoid this, total deformation can be accomplished in a series of steps in which the article is successively cold worked by a small amount and then process annealed in order to reduce hardness and increase ductility, thereby permitting further cold working as required.

Rolling

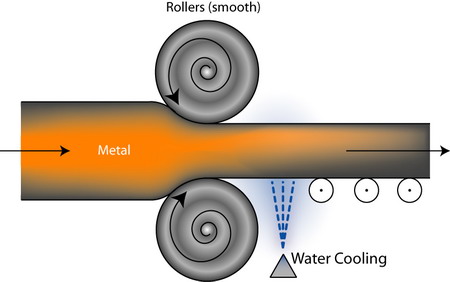

Rolling is the most widely used deformation process. It consists of passing metal between two rollers, which exert compressive stresses, reducing the metal thickness. Where simple shapes are to be made in large quantity, rolling is the most economical process. Rolled products include sheets, structural shapes and rails as well as intermediate shapes for wire drawing or forging. Circular shapes, ‘I’ beams and railway tracks are manufactured using grooved rolls.

Rolling

Rolling

Hot Rolling

Initial breakdown of an ingot or a continuously cast slab is achieved by hot rolling. Mechanical strength is improved and porosity is reduced. The worked metal tends to oxidise leading to scaling which results in a poor surface finish and loss of precise dimensions. A hot rolled product is often pickled to remove scale, and further rolled cold to ensure a good surface finish and optimise the mechanical properties for a given application.

HOT ROLLING

Reproduced from Materials Selection and Processing CD, by A.M.Lovatt, H.R.Shercliff and P.J.Withers.

![]()

Cold Rolling

Cold rolling is often used in the final stages of production. Sheets, strips and foils are cold rolled to attain dimensional accuracy and high quality surface finishes.

With softer metals such as lead and copper, a succession of cold-rolling passes can impose very large deformations. For many materials, however, the rolling sequence has to be interrupted for intermediate annealing in order to prevent fracture.

Forging

In this operation, a single piece of metal, normally hot, is deformed mechanically by the application of successive blows or by continuous squeezing. Forged articles range in size from nuts and bolts, hip replacement prostheses and crankshafts to (traditionally) gun barrels. Most engineering metals and alloys can be forged readily and include most steels, aluminium and copper alloys and certain titanium alloys including 6-4 (Ti-6 wt.%Al-4 wt%V) and 6-2-4-2 (Ti-6 wt.%Al-2 wt.%Sn-4 wt.%Zn-2 wt.%Mo). Strain-rate and temperature-sensitive materials, such as magnesium and nickel based superalloys, may require more sophisticated forging processes such as radial forging. Forged articles have excellent mechanical properties, combining fine grain structure with strengthening through strain hardening.

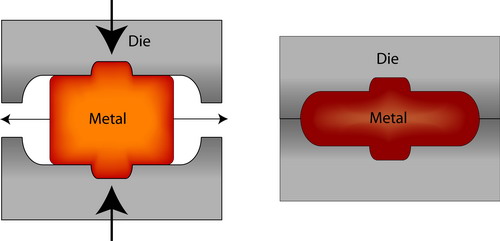

Closed Die

Closed-die forging

A force is brought to bear on a metal slug or preform placed between two (or more) die halves. The metal flows plastically into the cavity formed by the die and hence changes in shape to its finished shape. Examples of the machinery used include hydraulic presses, mechanical presses and hammers.

CLOSED DIE FORGING

Reproduced from Materials Selection and Processing CD, by A.M.Lovatt, H.R.Shercliff and P.J.Withers.

Possible geometries range from simple spherical blocks and discs to intricate components incorporating thin webs, holes, cavities, pockets and ribs. As metal flow is restricted by the die contours, closed-die forging can produce complex shapes and higher tolerances than the shapes and tolerances achieved using open-die forging processes.

Open Die

Open-die forging

Open-die forging is performed between flat dies with no pre-cut profiles. The dies do not confine the metal laterally during forging. Deformation is achieved through movement of the workpiece relative to the dies. Parts up to thirty metres in length can by hammered or pressed into shape in this way. Open-die forging comprises many process variations, enabling an extremely broad range of shapes and sizes to be produced. Unlike rolling operations, which generally produce continuous plates, sheets, strip, or various structural cross-sections, forging operations produce discrete parts.

In addition to round, square, rectangular, hexagonal bar and other basic shapes, open-die processes can produce:

- Spindles or rotors, whose diameter increases or decreases at multiple locations along the longitudinal axis.

- Hollows cylindrical in shape, usually with length much greater than the diameter of the part.

- Ring-like parts resembling washers or approaching hollow cylinders in shape, depending on the height:wall thickness ratio.

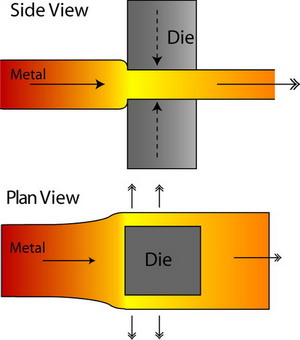

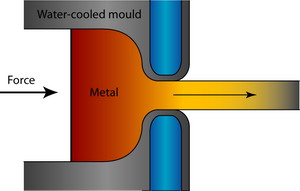

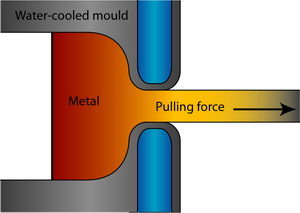

Extrusion

In extrusion, a bar or metal is forced from an enclosed cavity via a die orifice by a compressive force applied by a ram. Since there are no tensile forces, high deformations are possible without the risk of fracture of the extruded material. The extruded article has the desired, reduced cross-sectional area, and also has a good surface finish so that further machining is not needed. Extrusion products include rods and tubes with varying degrees of complexity in cross-section.

Extrusion

Examples of metals that can be extruded include lead, tin, aluminium alloys, copper, brass and steel. The minimum cross-sectional dimensions for extruded articles are approximately 3 mm in diameter for steel and 1 mm in diameter for aluminium. Some metals such as lead alloys and brass lend themselves to extrusion rather than drawing or rolling.

EXTRUSION

Reproduced from Materials Selection and Processing CD, by A.M.Lovatt, H.R.Shercliff and P.J.Withers.

Hot extrusion is carried out at a temperature T of approximately 0.6Tm and the pressures required range from 35 to 700 MPa. Under these demanding conditions, a lubricant is required to protect the die. Oil and graphite lubricants function well at temperatures up to 150°C, but borate glass or hexagonal boron nitride powders are favoured at higher temperatures where carbon-based lubricants oxidise.

Extruded products

Cold extrusion is performed at temperatures significantly below the melting temperature of the alloy being deformed, and generally at room temperature. The process can be used for most materials, provided that sufficiently robust machinery can be designed. Products of cold extrusion include aluminium cans, collapsible tubes and gear blanks.

Drawing

Drawing is the pulling of a metal piece through a die by means of a tensile force applied to the exit side. A reduction in cross-sectional area results, with a corresponding increase in length. A complete drawing apparatus may include up to twelve dies in a series sequence, each with a hole a little smaller than the preceding one. In multiple-die machines, each stage results in an increase in length and therefore a corresponding increase in speed is required between each stage. This is achieved using “capstans” which are used both to apply the tensile force and also to accommodate the increase in the speed of the drawn wire. These speeds may reach 60 ms–1.

Dies must be very hard so they tend to be made from steel or chilled cast iron. However, tungsten carbide and even diamond are increasingly used because of their greater ability to retain shape. A typical lubricant used for drawing is tallow, a soap/fat paste-type material that has a formulation of 5 wt% soap, 25 wt% oil, 25 wt% water, and 45 wt% solids.

Drawing

Metals can be formed to much closer dimensions by drawing than by rolling. Shapes ranging in size from the finest wire to those with cross-sectional areas of many square centimetres are commonly drawn. Larger artefacts may be drawn to square, round and even irregular cross sections. Drawn products include wires, rods and tubing products. Large quantities of steel and brass are cold drawn. Seamless tubing can be produced by cold drawing when thin walls and very accurate finishes are required.

Other processes

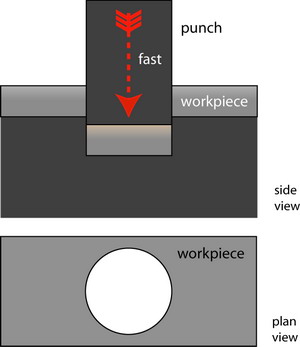

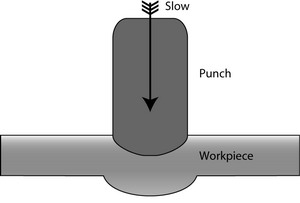

Stamping

Stamping is used to make high volume parts such as aviation or car panels or electronic components. Mechanical or hydraulic powered presses stamp out parts from continuous sheets of metal or individual blanks. The upper die is attached to the ram and the lower die is fixed. Whereas mechanical machinery transfers all energy as a rapid punch, hydraulic machinery delivers a constant, controlled force.

Stamping

![]()

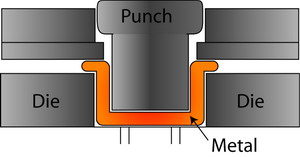

Deep Drawing

For deep drawing, the starting sheet of metal is larger than the area of the punch. A pressure plate, fixed to the machine, prevents wrinkling of the edges as the plug is drawn into a top die cavity. The outer parts of the sheet are drawn in towards the die as the operation proceeds. The process is limited by the possibility of fracture occurring during drawing; the maximum sheet width is rarely more that twice the die diameter.

Many shapes are possible including cups, pans, cylinders and irregular shaped products.

Deep drawing

![]()

Pressing

A sheet of metal is deformed between two suitably shaped dies usually to produce a cup or dish shaped component. A thick pad of rubber may replace one of the dies, giving reduced tooling costs and allowing larger deformations to be imposed.

Pressing

Summary

The production of the vast majority of metallic objects at some stage involves one of these four deformation processes:

- Rolling

- Extrusion

- Forging

- Drawing

The intention of this TLP is to introduce these four processes and to provide a brief description of their strengths, limitations and suitability for various applications.

Questions

Quick questions

You should be able to answer these questions without too much difficulty after studying this TLP. If not, then you should go through it again!

-

What would happen to a brittle metal such as white cast iron, if it were formed by closed die forging?

-

Discuss how the metal pieces of this article were made.

Deeper questions

The following questions require some thought and reaching the answer may require you to think beyond the contents of this TLP.

-

The melting temperature of a low-carbon steel is 1534°C. Above what temperature can we use hot working to form it, and why?

-

What processes could be used to make this shape? What else could affect the choice of process?

-

At 30 ms–1, what weight of 1 mm diameter copper wire could be drawn in an hour? The density of copper is 8920 kg m–3.

-

Do you think steel reinforcing bars for concrete are drawn or extruded?

Going further

CD-ROM

- Lovatt A.M., Shercliff H.R. and Withers P.J. (2000), "Material Selection and Processing", CD-ROM and supporting booklets, Technology Enhancement Programme (part of Gatsby Technical Education Project), London.

Academic consultant: Kevin Knowles (University of Cambridge)

Content development: Andrew Bennett, Joanne Sharp

Web development: Jin Chong Tan

2D Illustrations: Kathy Mather