Re-use of this resource is governed by a Creative Commons

Attribution-

Noncommercial-Share Alike 4.0 Licence International

https://creativecommons.org/licenses/by-nc-sa/4.0/

Noncommercial-Share Alike 4.0 Licence International

https://creativecommons.org/licenses/by-nc-sa/4.0/

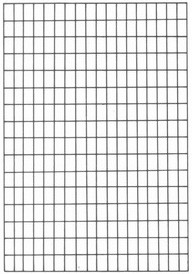

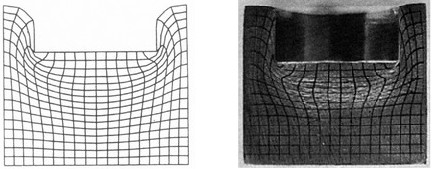

FE simulation of a 4-Stage Forging Process

The production of gudgeon pins (the pins that hold together

the two halves of a hinge) can be visualised well with the help of a

finite-element mesh.

Stage 1: Upsetting

The starting billet is compressed until it fills the

die into which it has been placed.

Reproduced with permission - Figs 7.54, 7.55, 7.57 from

Rowe, Sturgess, Hartley and Pillinger [2]. Cambridge University Press

FE simulation of a 4-Stage Forging Process

The production of gudgeon pins (the pins that hold together

the two halves of a hinge) can be visualised well with the help of a

finite-element mesh.

Stage 1: Upsetting

The starting billet is compressed until it fills the

die into which it has been placed.

Reproduced with permission - Figs 7.54, 7.55, 7.57 from

Rowe, Sturgess, Hartley and Pillinger [2]. Cambridge University Press

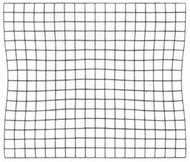

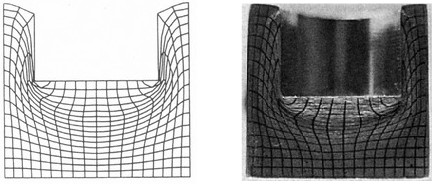

FE simulation of a 4-Stage Forging Process

The production of gudgeon pins (the pins that hold together

the two halves of a hinge) can be visualised well with the help of a

finite-element mesh.

Stage 2: Indentation

The billet is indented, providing a guide for the punch

in the following stage.

Reproduced with permission - Figs 7.54, 7.55, 7.57 from

Rowe, Sturgess, Hartley and Pillinger [2]. Cambridge University Press

FE simulation of a 4-Stage Forging Process

The production of gudgeon pins (the pins that hold together

the two halves of a hinge) can be visualised well with the help of a

finite-element mesh.

Stage 2: Indentation

The billet is indented, providing a guide for the punch

in the following stage.

Reproduced with permission - Figs 7.54, 7.55, 7.57 from

Rowe, Sturgess, Hartley and Pillinger [2]. Cambridge University Press

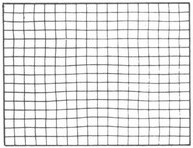

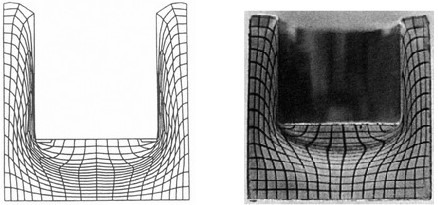

FE simulation of a 4-Stage Forging Process

The production of gudgeon pins (the pins that hold together

the two halves of a hinge) can be visualised well with the help of a

finite-element mesh.

The grid distortions produced during the various process

stages agree very well with experimentally observed distorted grids.

Stage 3: Backward Extrusion

The indented slug is backward extruded leaving a cup

shape.

Reproduced with permission - Figs 7.54, 7.55, 7.57 from

Rowe, Sturgess, Hartley and Pillinger [2]. Cambridge University Press

FE simulation of a 4-Stage Forging Process

The production of gudgeon pins (the pins that hold together

the two halves of a hinge) can be visualised well with the help of a

finite-element mesh.

The grid distortions produced during the various process

stages agree very well with experimentally observed distorted grids.

Stage 3: Backward Extrusion

The indented slug is backward extruded leaving a cup

shape.

Reproduced with permission - Figs 7.54, 7.55, 7.57 from

Rowe, Sturgess, Hartley and Pillinger [2]. Cambridge University Press

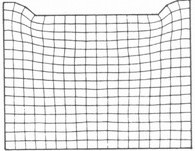

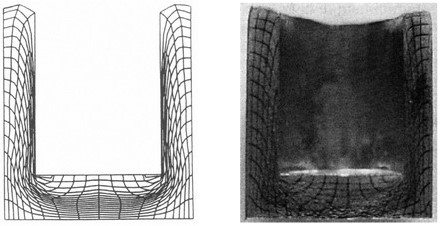

FE simulation of a 4-Stage Forging Process

The production of gudgeon pins (the pins that hold together

the two halves of a hinge) can be visualised well with the help of a

finite-element mesh.

The grid distortions produced during the various process

stages agree very well with experimentally observed distorted grids.

Stage 3: Backward Extrusion

The indented slug is backward extruded leaving a cup

shape.

Reproduced with permission - Figs 7.54, 7.55, 7.57 from

Rowe, Sturgess, Hartley and Pillinger [2]. Cambridge University Press

FE simulation of a 4-Stage Forging Process

The production of gudgeon pins (the pins that hold together

the two halves of a hinge) can be visualised well with the help of a

finite-element mesh.

The grid distortions produced during the various process

stages agree very well with experimentally observed distorted grids.

Stage 3: Backward Extrusion

The indented slug is backward extruded leaving a cup

shape.

Reproduced with permission - Figs 7.54, 7.55, 7.57 from

Rowe, Sturgess, Hartley and Pillinger [2]. Cambridge University Press