Optical anisotropy in polymers

For a polycarbonate with a relatively simple carbon-carbon backbone, the refractive index is larger for vibrations of the electric field in the light wave (the electric vector) parallel to the axis of the chain. The applied stress causes alignment of the random chains and the inherent uniaxial anisotropy of the chain structure leads to 'stress-induced birefringence'. Birefringence in polycarbonate specimens arises due to two effects, non-random chain alignments and residual strains. To minimise pre-existing strains the polycarbonate specimens used in these demonostrations were annealed to remove any strains incorporated during their fabrication.

Question

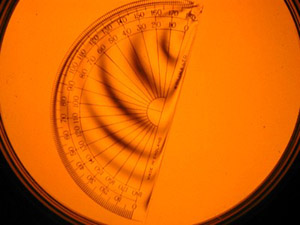

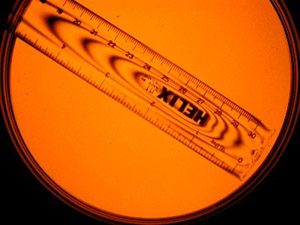

Study the isoclinic fringes from both the protractor and ruler. How do you think these articles were manufactured, and does the stress distribution support this? (Answer below)

Protractor viewed through plane polariscope. |

Ruler viewed through plane polariscope. |

Answer

Common processing routes such as injection moulding and extrusion lead to a residual stress distribution. Plastic rulers and protractors have residual strains due to their production by either extrusion or injection moulding. When observed under crossed polars they display birefringence, which enables the point of injection to be determined.

Induced optical anisotropy

In response to an applied stress a substance may change its dielectric constant and consequently, in transparent materials, change its refractive index. For an initially 'isotropic material, when a tensile stress is applied the material will become uniaxial with the optic axis parallel to the applied stress. In the general case, and where the stresses are applied in a plane, the optical birefringence will be proportional to the difference between the two (orthogonal) principal stresses in the plane. This is called the Stress-Optic Law. The constant of proportionality is known as the stress-optical coefficient.