Re-use of this resource is governed by a Creative Commons

Attribution-

NonCommercial-ShareAlike 4.0 International

https://creativecommons.org/licenses/by-nc-sa/4.0/

NonCommercial-ShareAlike 4.0 International

https://creativecommons.org/licenses/by-nc-sa/4.0/

Transmission lines

Problem: You need to transmit electrical power

100km, while minimising cost. What material for the cable?

Total cost = Number of pylons × Pylon cost +

sectional area of cable × length of cable × density of cable × cost per unit mass of raw materials +

(processing cost + land purchase + labour + maintenance + protective coatings + substations + insulators + more = constant)

Clearly, the ideal material would be low density, strong in tensile loading, high conductivity, and low cost. Unfortunately, it doesn't exist, so a compromise is needed. Compare some of the potential materials that could be used:

Total cost = Number of pylons × Pylon cost +

sectional area of cable × length of cable × density of cable × cost per unit mass of raw materials +

(processing cost + land purchase + labour + maintenance + protective coatings + substations + insulators + more = constant)

Clearly, the ideal material would be low density, strong in tensile loading, high conductivity, and low cost. Unfortunately, it doesn't exist, so a compromise is needed. Compare some of the potential materials that could be used:

Materials available

(mouseover)

(mouseover)

Copper

Steel

Aluminium

Gold

Lead

Silver

Nb/Sn

Superconductor

Superconductor

Move your mouse over a material to find out relevant electrical information

Typically used for home wiring, has a very high conductivity, and good mechanical properties, especially when alloyed. Price has increased in recent years.

When exposed to air, it will form an oxide layer and corrode. Used in nearly all electronics as the conductor on printed circuit boards - because copper is easy to dissolve!

Many different steels exist, this is a general steel. Due to alloying elements, the electrical conductivity is lowered.

Yield strength is very high, however, so potenially fewer pylons would be needed.

Overall, much better used for it's mechanical properties, which can be altered by adjusting composition and heat treatment.

Strong and light, typically alloyed with silicon

to increase yield strength.

Density is 1/3 that of copper

Conductivity 2/3 that of copper

Alloying can increase strength significantly - at a cost to conductivity.

Can be used in place of copper where weight (or cost) is crucial- such as in aeroplanes.

One of the best conducuctors, and does not corrode. Unfortunately, it is very dense, ductile, expensive, and in limited supply.

Better suited to microchip bonding wires - they are small, non load bearing, and to make the connections, ductile.

Widely used as a thin coating on plugs and sockets as it does not corrode.

Unsuitable for wiring. Dense, poorly conducting, very weak.

It is used in lead-acid batteries for it's chemical properties, not electrical conductance.

Until recently, was widely used in electronic devices as part of solder, a eutectic mixture of tin and lead. Use is forbidden via the 'Restriction of Hazardous Substances Directive' since 2003.

The best electrical conductor!

Unfortunately, poor mechanical properties, high cost, limited supply, and corrosion limit it's use in electrical systems.

This is special- it's a superconductor (type 1) Accordingly, it needs cooling (lq He)! While higher temperature superconductors exist (lq N2), they typically are ceramics, and much harder to shape into a flexible wire.

Used as the LHC's superconducting magnets, along with 120 tons of liquid helium.

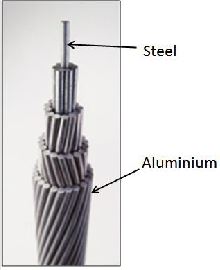

Which is really used?

None of the individual materials have the desired properties!

Instead, a combination is used: Aluminium cables with a steel core:

Instead, a combination is used: Aluminium cables with a steel core:

Image courtesy of National Grid Transco

Other large scale power transmission

Depending on the price at the time, underground power

lines often use copper. Mechanical strength is less important when the

ground is supporting the cable.

A 600m superconducting power cable has been in use in New York since 2008.

They are useful for constrained spaces, and thermal insulation keeps the cost of cooling low.

From a 2002 report - Cost of constructing >220kV transmission lines was €200,000-800,000 per km!

A 600m superconducting power cable has been in use in New York since 2008.

They are useful for constrained spaces, and thermal insulation keeps the cost of cooling low.

From a 2002 report - Cost of constructing >220kV transmission lines was €200,000-800,000 per km!

Case study: Italian 380kV line, 2002.

Distance between towers 400-450 metres.

Significant contribution to costs (all in Euro/km)

Source:http://ec.europa.eu/energy/electricity/publications/doc/comp_cost_380kV_en.pdf

Distance between towers 400-450 metres.

Significant contribution to costs (all in Euro/km)

| Towers: | 47,000 |

| Conductors: | 48,000 |

| Insulators: | 8,000 |

| Equipment: | 20,000 |

| Labour: | 105,000 |

| Rights-of-way: | 25,000 |

| Construction costs: | 20,000 |

| Total (Euro/km): | 273,000 |

Source:http://ec.europa.eu/energy/electricity/publications/doc/comp_cost_380kV_en.pdf