Friction - properties of the coefficient of friction, μ

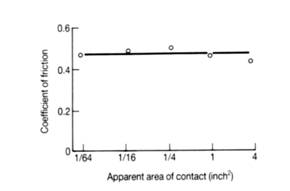

Experimental data showing the invariance of the coefficient of friction with the apparent area of contact for wooden sliders on an unlubricated steel surface (Hutchings, p. 24; from E. Rabinowicz, Friction and Wear of Materials, 1965).

This can be understood by considering a brick on a table. When the large side of the brick is in contact with the table the apparent contact area is large and there are many asperities that support the load. When the smaller side is in contact the apparent contact area is lower and there are fewer asperities. This causes a greater effective normal load on each asperity (same weight but fewer asperities) which results in the area of each asperity being larger. This means the true contact area is essentially the same, hence so is the friction.

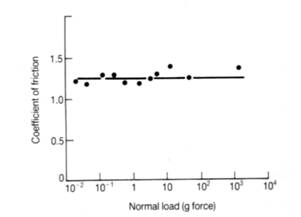

Experimental data showing the invariance of the coefficient of friction with normal load for the unlubricated sliding of steel on aluminium. μ is unaffected but the frictional force increases.

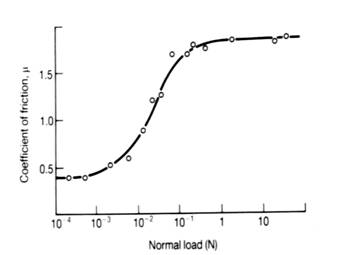

However there are special cases where μ experiences a transition in value as the normal load changes:

The variation of the coefficient of friction with applied normal load for copper sliding against copper. At low loads, the two metal surfaces are separated by thin oxide films. At high loads, metallic contact occurs between copper asperities as the oxide films are penetrated (Hutchings, p. 37; from J.R. Whitehead, ‘Surface deformation and friction of metals at light loads’, Proc. Roy. Soc. Lond. A201, 109-124, 1950). A high coefficient of friction results because of the plastic deformation of the contacting metallic surfaces. μ is independent of load except at the transition region.

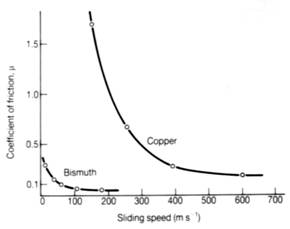

The effect of sliding speed on the coefficient of friction for pure bismuth and pure copper sliding against themselves (Hutchings, p. 42; from F.P. Bowden and D. Tabor, The Friction and Lubrication of Solids, Part II, 1964). At very high speeds, the dissipation of frictional work can raise the temperature at the interface to beyond the melting point of the material involved. Sliding then takes place under hydrodynamic lubrication conditions (see lubrication).

Typically, μ » 0.4-1.5 for one metal sliding against another.