Simulation of Weibull modulus experiment

In the simulation below it shows an experiment that can be done to see how a material fails in compression and the scatter of loads it requires.

In the simulation above the failure crack was shown to break directly across the material in reality the material is more likely to break in more of a ‘Y’ shape. This phenomenon is known as compression curl or cantilever curl. There is not much quantitative data about why this occurs however this is seen when many materials break.

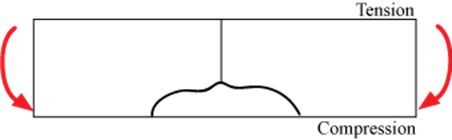

The rod was loaded in bending, placing the top in compression and the bottom in tension. The crack would have started to grow from the side under tension. However instead of breaking straight through the crack splits and propagates to two points on the compression side creating the characteristic ‘y’ shape fracture. One explanation for this is, that as the crack moves through to the compressive side the stresses cannot be relaxed fast enough, as it is a high speed failure, so the crack can split and take a longer route and this is known as compression curl. The characteristic shape can be useful to identify the side that was in tension in failed samples.

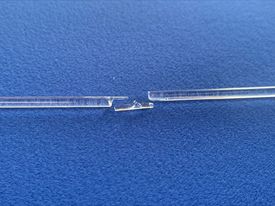

The images below show the results of compression curl on Perspex that was put into uniaxial compression.

Fracture path in perspex put in uniaxial compression

Fracture pieces of perspex after it was put in uniaxial compression