Micrograph Library

Browse the libraryAdvanced searchSystemsCompositionsTechniquesKeywordsPhase diagramsHelpPreferencesAbout the micrograph libraryTerms of useContribute micrographs!FeedbackLinksCredits Print this page

Full Record for Micrograph 156

[232 KB]

View micrograph

.. in new window

View micrograph and record

.. in new window

You can also view and download the micrographs on Flickr

- Micrograph no

- 156

- Brief description

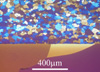

- Roll-bonded aluminium alloy diffusion couple annealed for 30 minutes at 600ºC.

- Keywords

- alloy

, aluminium

, aluminium  , diffusion couple

, diffusion couple  , metal, recrystallisation

, metal, recrystallisation  , roll-bonding

, roll-bonding

- Categories

- Metal or alloy

- System

- Al-Fe-Mn/Al-Si

- Composition

- Al, Fe 0.5, Mn 1.0 / Al, Si 1.0 (wt%)

- Standard codes

- Reaction

- Processing

- Mechanical roll-bonding followed by annealing at 600ºC for 30 minutes

- Applications

- The couple was made to investigate diffusion of silicon through the Al-0.5Fe-1.0Mn (wt.%) alloy during annealing.

- Sample preparation

- Electrolytically etched using Barker's reagent.

- Technique

- Cross-polarised light microscopy

- Length bar

- 400 μm

- Further information

- This micrograph shows the grain structure of a roll-bonded aluminium alloy diffusion couple annealed for 30 minutes at 600ºC. The upper half of the couple is Al-0.5Fe-1.0Mn (wt.%), the lower half is Al-1.0Si (wt.%). Annealing has recrystallised the microstructure. The Al-Fe-Mn alloy has many intermetallic particles (the dark phase). These help create recrystallisation nuclei, hence this alloy has a high density of small grains relative to the Al-Si alloy.

The Barker's etch produces a thick oxide layer on the grains of aluminium (anodising). When viewed in cross-polarised light, interference in the oxide layer produces colours which depend on grain orientation, hence the grain structure is imaged. Strain of the aluminium matrix during rolling around the intermetallic particles in the Al-Fe-Mn alloy produces a high density of dislocations. Because recovery of the dislocations creates nuclei for recrystallisation, this high defect density results in a much finer recrystallised grain structure than in the particle-free Al-Si alloy. - Contributor

- D T L Alexander

- Organisation

- Department of Materials Science and Metallurgy, University of Cambridge

- Date

- 21/05/02

- Licence for re-use

Attribution-NonCommercial-ShareAlike 4.0 International

Attribution-NonCommercial-ShareAlike 4.0 International- Related micrographs