Micrograph Library

Browse the libraryAdvanced searchSystemsCompositionsTechniquesKeywordsPhase diagramsHelpPreferencesAbout the micrograph libraryTerms of useContribute micrographs!FeedbackLinksCredits Print this page

Micrograph 289 and full record

- Micrograph no

- 289

- Brief description

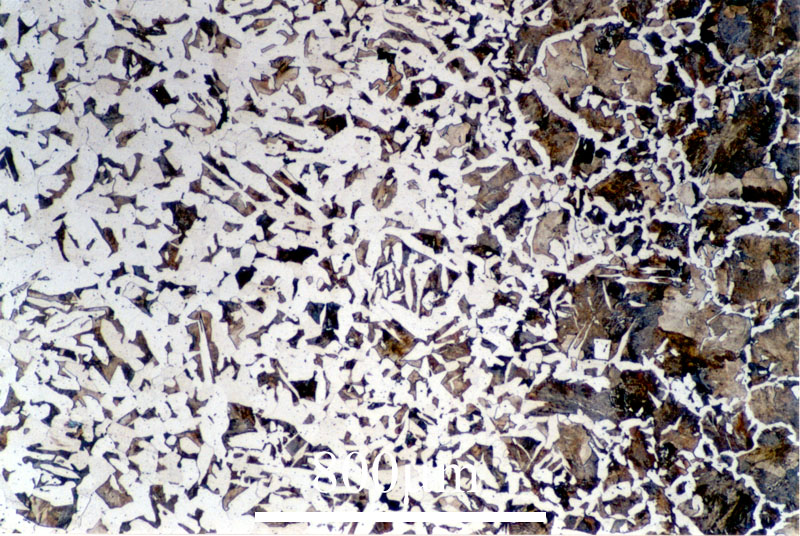

- Fe, C 0.15 (wt%) steel, carburised

- Keywords

- alloy

, carbon, carburisation

, carbon, carburisation  , iron, metal, steel

, iron, metal, steel

- Categories

- Metal or alloy

- System

- Fe-C-X

- Composition

- Fe, C 0.15 (wt%)

- Standard codes

- Reaction

- Processing

- Case hardened

- Applications

- Sample preparation

- Nital

- Technique

- Reflected light microscopy

- Length bar

- 800 μm

- Further information

- After initial casting of this steel it was subject to a process known as carburisation. The metal is heated to above the ferrite-austenite transition in a carbon atmosphere. This establishes a concentration gradient and hence carbon diffuses into the steel. Usually the steel is then hardened by quenching. This produces what is known as a case hardened steel - with a hard surface (case) surrounding a tough core. The carbon gradient can be seen in the changing shade of the sample from left to right, with high carbon concentration at the right (surface) and hence a martensitic phase, changing to the lighter shade consisting of mostly ferrite.

- Contributor

- Dr R F Cochrane

- Organisation

- Department of Materials, University of Leeds

- Date

- 04/09/02

- Licence for re-use

Attribution-NonCommercial-ShareAlike 4.0 International

Attribution-NonCommercial-ShareAlike 4.0 International- Related micrographs

View image alone .. in a new window

Help is available on downloading images