Micrograph Library

Browse the libraryAdvanced searchSystemsCompositionsTechniquesKeywordsPhase diagramsHelpPreferencesAbout the micrograph libraryTerms of useContribute micrographs!FeedbackLinksCredits Print this page

Micrograph 72 and full record

- Micrograph no

- 72

- Brief description

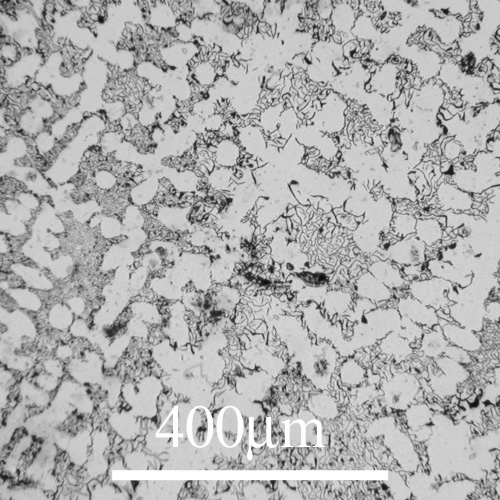

- Ni-hard iron

- Keywords

- alloy

, cast iron

, cast iron  , dendrite

, dendrite  , iron, metal, Ni-hard iron

, iron, metal, Ni-hard iron  , nickel

, nickel - Categories

- Metal or alloy

- System

- Fe-C-X

- Composition

- Fe, C 2.8, Ni 4.5, Mn 1.2, Cr 0.75, Si 0.5, P 0.3, Mo 0.25, S 0.1 (wt% typical) (Ni-hard iron)

- Standard codes

- Reaction

- Processing

- Applications

- Sample preparation

- Technique

- Reflected light microscopy

- Length bar

- 400 μm

- Further information

- This is a Ni-hard iron, one of the first cast irons to be developed. These white irons contain Ni to ensure that the austenite transforms to martensite following heating and chromium to increase the hardness of the eutectic carbide.

Ni-hard irons are normally stress relieved at 200-300 °C for approximately four hours to relieve the martensitic transformation stresses and to promote the transformation of retained austenite. The structure consists of proeutectic austenite dendrites containing martensitic needles with interdendritic austenite-martensite/carbide eutectic. - Contributor

- Prof T W Clyne

- Organisation

- Department of Materials Science and Metallurgy, University of Cambridge

- Date

- 25/10/01

- Licence for re-use

Attribution-NonCommercial-ShareAlike 4.0 International

Attribution-NonCommercial-ShareAlike 4.0 International- Related micrographs

View image alone .. in a new window

Help is available on downloading images