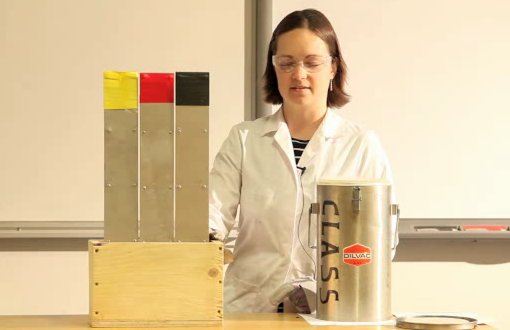

Equipment and facilities needed for the demonstration

The equipment required is simple, although clearly the experiment does need a fair amount of preparation - at least the first time it is carried out! It's important that there should not be any significant leakage from the box. A simple wooden construction should be adequate, provided the jointing is good. Clearly it would also be possible to make it of metal (although it's worth noting that there may then be a greater danger than is the case with a wooden box of acquiring a "burn" from it via contact with unprotected skin while cold). A plastic construction would also be possible, particularly if a moulded box with suitable dimensions could be found. (Some plastics, however, become very brittle at liquid nitrogen temperatures.) The (external) dimensions of the box used are 300 mm long by 190 mm deep by 150 mm wide, although clearly none of these dimensions are critical. They just need to be suitable to accommodate the strips, which in this case were about 70 mm wide by 500 mm long, and also to hold a suitable depth of liquid nitrogen.

It's best for the strips to be fairly long, so that the behaviour can clearly be seen by the audience, although it's perhaps worth noting that, depending on the depth of the liquid nitrogen, it may be that the full length of the strips do not cool down significantly. The uncooled parts help to illustrate the behaviour, even if they do not have the correct, or any, curvature. Another practical point to note is that if the box is large in section then it may require quite a lot of liquid nitrogen to fill it to a suitable depth. The capacity of the box used in the demonstration shown is about 4 litres, which is probably about as much liquid nitrogen as can conveniently be handled in a lecture theatre.

Each of the individual strips used is 1 mm in thickness. Sheet material with this thickness is in general easily obtainable. Thinner sheet could be used, and would lead to higher curvatures, but there might be a danger of plastic deformation arising, particularly with the aluminium, and this would cause some problems. Thicker sheet, on the other hand, will reduce the curvature and make the deflections less noticeable. Some attention should also be paid to the joining of the pairs of strips. Adhesive joining could be attempted, but it should be noted that substantial shear forces are generated during cooling, plus the adhesive is likely to become brittle at low temperature. The upshot of this is that debonding is likely to occur, even if the bonding process is carried out very carefully. The best solution is probably to use rivets. A set of about half a dozen down each side should be adequate. Rivets can be used in combination with adhesive bonding.

It may add to the interest level if the audience are asked beforehand to nominate which of the three bi-material strips will give the largest curvature. Identifying the correct answer (the Al-PC combination) does require an appreciation that both a large difference in expansivity and a small ratio between the two stiffnesses will favour a high curvature. Probably most of the audience will be unlikely to spot this immediately, and so the outcome may be a surprise to them.

There are, of course, some safety issues and a risk assessment form should be completed. It's certainly a good idea to practice the demonstration beforehand, in the location concerned. A lab-coat, goggles and gloves should be worn. However, minor spills of liquid nitrogen are unlikely to cause any major hazards and in general this is expected to be a safe and straightforward experiment to carry out.