Micrograph Library

Browse the libraryAdvanced searchSystemsCompositionsTechniquesKeywordsPhase diagramsHelpPreferencesAbout the micrograph libraryTerms of useContribute micrographs!FeedbackLinksCredits Print this page

Micrograph 722 and full record

- Micrograph no

- 722

- Brief description

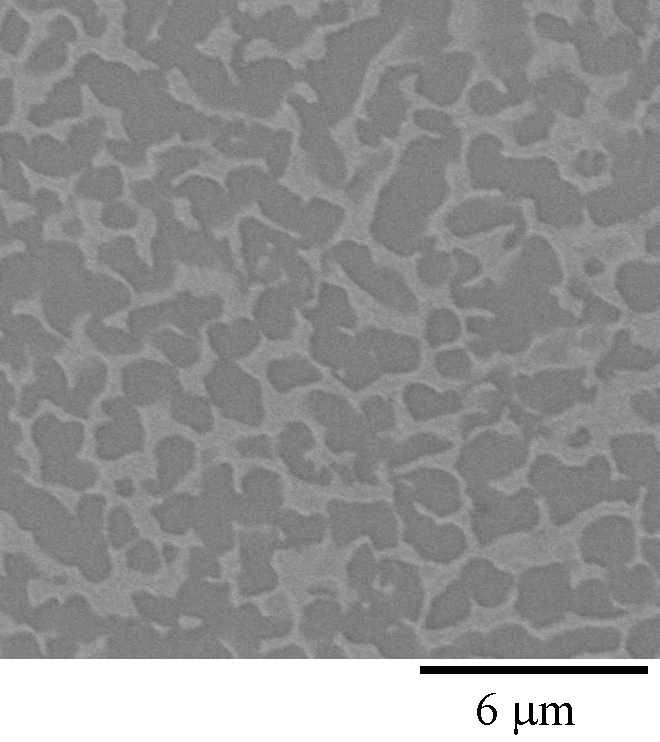

- Ni-Superalloy

- Keywords

- creep

, nickel, single crystal

, nickel, single crystal - Categories

- Metal or alloy

- System

- Ni-X

- Composition

- Ni, Al, Re, W, Ta, Cr, Co, Ru (Ni-Superalloy)

- Standard codes

- Reaction

- Processing

- Solution heat treated, creep test

- Applications

- The single crystal superalloy can undergo microstructural changes when it’s stressed at high temperature, the phenomena is called "rafting", which can be good for high temperature (above 1050°C) and low stress (100 MPa) conditions.

- Sample preparation

- Standard polishing procedure

- Technique

- Field emission gun scanning electron microscopy (FEGSEM) in secondary electron imaging (SEI) mode

- Length bar

- 6 μm

- Further information

- This image shows the microstructure of a crept Ni-base superalloy. The g' phase has rafted.

- Contributor

- A C Yeh

- Organisation

- Rolls-Royce University Technology Centre, Department of Materials Science and Metallurgy, University of Cambridge

- Date

- 05/03/03

- Licence for re-use

Attribution-NonCommercial-ShareAlike 4.0 International

Attribution-NonCommercial-ShareAlike 4.0 International- Related micrographs

View image alone .. in a new window

Help is available on downloading images