Slip: resolved shear stress and Schmid factor, Taylor factor

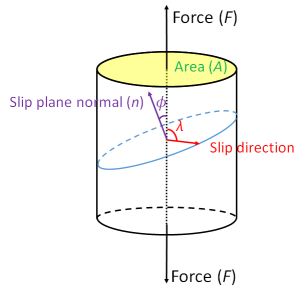

Figure 11. Slip geometry

Consider a single crystal with numerous dislocations, with a stress applied to it at an arbitrary angle. Each available slip system will experience a resolved shear stress acting in the associated slip plane in the slip direction.

The slip plane normal makes an angle \( \phi \) with the tensile axis, so the area of the plane is \( A{\left( {{\rm{cos}}\phi } \right)^{}}^{ - 1} \).

If the slip direction is at an angle of \( \lambda \) to the tensile axis then the resolved component of the applied force, \( F \), parallel to the slip direction is \( F \rm{cos} \lambda \).

Therefore, the resolved component of the shear stress on the slip planes acting parallel to the slip direction, \( \tau _{\rm{R}} \).

\[ {\tau _{\rm{R}}} = \frac{{F{\rm{cos}}\lambda }}{{A{{\left( {{\rm{cos}}\phi } \right)}^{}}^{ - 1}}} = \sigma {\rm{cos}}\lambda {\rm{cos}}\phi \]

Schmid's Law states that the value of \( \tau _{\rm{R}} \) at which slip occurs in a given material with specified dislocation density and purity is a constant, known as the critical resolved shear stress,\( \tau _{\rm{c}} \).

\[ {\tau _{\rm{c}}} = {\sigma _{\rm{y}}}{\rm{cos}}\lambda {\rm{cos}}\phi \]

Where \( {\rm{cos}}\lambda {\rm{cos}}\phi \) is called the Schmid factor and \( \sigma_y \) is the yield stress.

Note that the Schmid factor can have a value between 0 and 0.5.

Since the critical resolved shear stress for all slip systems is the same, Schmid’s law indicates that the slip system with the highest Schmid factor would yield first. Such as slip system is called the primary slip system.

The stress required to cause slip on the primary slip system is the yield stress of the single crystal. If the stress is increased beyond the yield stress, other slip systems may become operative. For a more detailed description of slip in single crystals, click here.

For polycrystalline materials with randomly orientated grains, the average value of the Schmid factor is ~⅓. This average value is referred to as the Taylor factor and so it might be expected that the yield stress and the critical resolved shear stress for polycrystalline materials would be related as follows:

\[ \sigma_\rm{y} \approx 3{\tau_\rm{c}} \]

However, in practice, the yield stress of a polycrystalline metal is often much higher than this, due to the effect of grain boundaries. In a polycrystal, the deformation of each individual grain has to be compatible with that of its neighbours, which can lead to a significant constraint. Multiple slip is normally required from the outset in virtually all grains in order to satisfy this requirement and, thus, substantially higher stresses are required for yielding and subsequent plasticity of polycrystals than those needed for single crystals.