Micrograph Library

Browse the libraryAdvanced searchSystemsCompositionsTechniquesKeywordsPhase diagramsHelpPreferencesAbout the micrograph libraryTerms of useContribute micrographs!FeedbackLinksCredits Print this page

Full Record for Micrograph 610

[178 KB]

View micrograph

.. in new window

View micrograph and record

.. in new window

You can also view and download the micrographs on Flickr

- Micrograph no

- 610

- Brief description

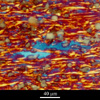

- Section of a metal matrix composite (MMC)

- Keywords

- annealing

, cold swaging, composite material

, cold swaging, composite material  , extrusion

, extrusion  , MMC, particle, SiC, silicon carbide

, MMC, particle, SiC, silicon carbide - Categories

- Composite

- System

- Al

- Composition

- Commercial purity (99.5%) + 15 micron angular silicon carbide particles

- Standard codes

- Reaction

- N/A

- Processing

- Commercial purity (99.5%) aluminium has been atomised, mixed with SiC reinforcement particles, tumbled for 12 hours, cold compacted (20MPa) into an evacuated can, extruded, annealed, cold swaged (strain=0.75) and then heat treated (1h 350 degrees C)

- Applications

- Metal matrix composites (MMCs) offer high specific stiffness which can be retained to high temperatures. This makes them suitable for applications in the aerospace industry. They also offer controlled (or zero) thermal expansion coefficients, good wear resistance and good impact properties.

- Sample preparation

- The sample has been oxidised to provide colour contrast for different grain orientations.

- Technique

- Reflected light microscopy, polarised

- Length bar

- 40 μm

- Further information

- The extrusion and cold swaging processes lead to the elongation of grains. This micrograph shows a longitudinal section with the working direction lying horizontal. Since the material has only been annealed for 1h at 350 degrees C, recrystallisation has only just started. Nucleation occurs at the reinforcement particles but there is no clear preference for nucleation at highly angular particles or particles with high aspect ratios. It was also noted that recrystallisation occurs preferentially at the surface of cold swaged specimens, probably due to strain localisation.

- Contributor

- Prof T W Clyne

- Organisation

- Department of Materials Science and Metallurgy, University of Cambridge

- Date

- 03/10/02

- Licence for re-use

Attribution-NonCommercial-ShareAlike 4.0 International

Attribution-NonCommercial-ShareAlike 4.0 International- Related micrographs