Micrograph Library

Browse the libraryAdvanced searchSystemsCompositionsTechniquesKeywordsPhase diagramsHelpPreferencesAbout the micrograph libraryTerms of useContribute micrographs!FeedbackLinksCredits Print this page

Micrograph 733 and full record

- Micrograph no

- 733

- Brief description

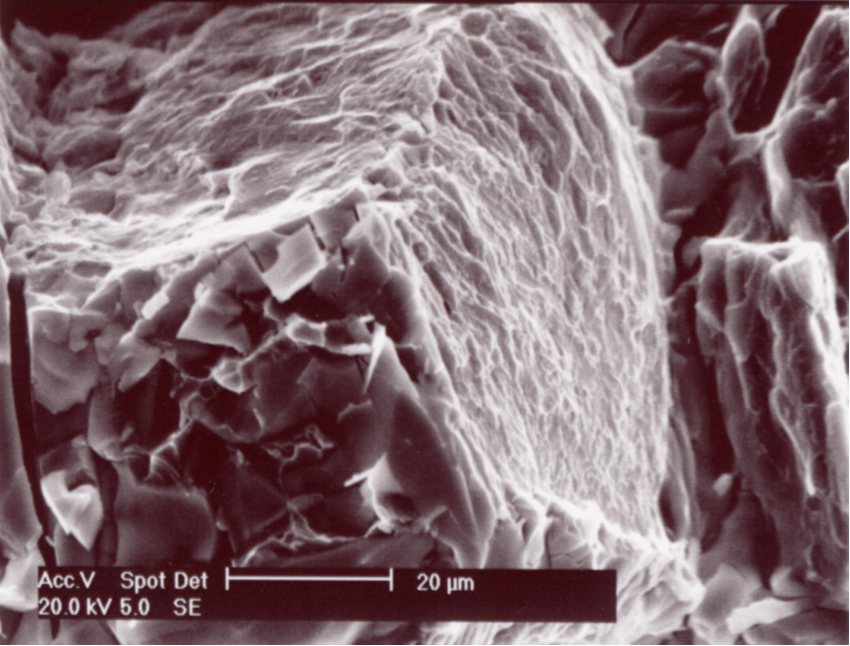

- Magnesium alloy, fracture surface

- Keywords

- magnesium

- Categories

- Fracture, Metal or alloy

- System

- Mg-Zn

- Composition

- Mg 94.05, Zn 5.62, Zr 0.19, Ce 0.10, Nd 0.03 (wt%) (RZ5 Alloy)

- Standard codes

- Reaction

- Processing

- Tensile test at room temperature.

- Applications

- RZ5 magnesium alloy is commonly used for wheels in both Formula One and Super-bike competitions because of its high strength to weight ratio.

- Sample preparation

- None: fracture surface.

- Technique

- Scanning electron microscopy (SEM) in backscattered electron imaging (BEI) mode

- Length bar

- 20 μm

- Further information

- This micrograph shows the brittle nature associated with the grain boundary phase, rich in zinc and rare earths. During tensile testing below 200°C the grains deform plastically but the boundaries remain elastic. This manifests itself with the growth of voids at the grain boundary phase/grain interface which link up and cause failure by the brittle intergranular fracture mode III method. Here the grain boundary phase can be clearly seen to be spalling off of the grain.

- Contributor

- R J Mitchell

- Organisation

- Department of Engineering, University of Leicester

- Date

- 05/03/03

- Licence for re-use

Attribution-NonCommercial-ShareAlike 4.0 International

Attribution-NonCommercial-ShareAlike 4.0 International- Related micrographs

View image alone .. in a new window

Help is available on downloading images