Micrograph Library

Browse the libraryAdvanced searchSystemsCompositionsTechniquesKeywordsPhase diagramsHelpPreferencesAbout the micrograph libraryTerms of useContribute micrographs!FeedbackLinksCredits Print this page

Full Record for Micrograph 574

[77 KB]

View micrograph

.. in new window

View micrograph and record

.. in new window

You can also view and download the micrographs on Flickr

- Micrograph no

- 574

- Brief description

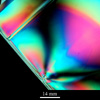

- Injection-moulded polystyrene (PS) case

- Keywords

- alignment, birefringence

, injection moulding

, injection moulding  , polymer

, polymer  , polystyrene (PS), sprue

, polystyrene (PS), sprue - Categories

- Polymer

- System

- Polystyrene (PS)

- Composition

- Not specified

- Standard codes

- Reaction

- Processing

- Polystyrene was injected into a mould via a noticeable 'sprue'

- Applications

- Polystyrene is hard and inexpensive and its use is very widespread. CD cases and clear plastic cups are common examples. Domestic appliance casings are also typically made from PS

- Sample preparation

- Technique

- Cross-polarised light microscopy

- Length bar

- 14 mm

- Further information

- The colours in the image are the result of birefringence and relate to the residual strain in the polystyrene. The pattern of strain is indicative of the flow of material during the injection process and it highlights the injection point (known as a 'sprue') which can also be identified by a small lump on the surface; the molecular alignment is greatest near this point. Towards the edges of the ruler and along its length, the material becomes more relaxed and as the molecular alignment falls, the retardation of light is less. If heated above the glass transition temperature of polystyrene (about 100 deg C), the material will tend to relax, particularly near the sprue. This will result in a wrinkling of the component.

- Contributor

- J A Curran

- Organisation

- Department of Materials Science and Metallurgy, University of Cambridge

- Date

- 03/10/02

- Licence for re-use

Attribution-NonCommercial-ShareAlike 4.0 International

Attribution-NonCommercial-ShareAlike 4.0 International