Micrograph Library

Browse the libraryAdvanced searchSystemsCompositionsTechniquesKeywordsPhase diagramsHelpPreferencesAbout the micrograph libraryTerms of useContribute micrographs!FeedbackLinksCredits Print this page

Full Record for Micrograph 591

[152 KB]

View micrograph

.. in new window

View micrograph and record

.. in new window

You can also view and download the micrographs on Flickr

- Micrograph no

- 591

- Brief description

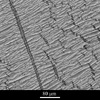

- Crazing near a fracture surface in polycarbonate

- Keywords

- craze

, fibril

, fibril  , fracture

, fracture  , polycarbonate (PC), polymer

, polycarbonate (PC), polymer

- Categories

- Fracture, Polymer

- System

- Polycarbonate (PC)

- Composition

- Not specified

- Standard codes

- Reaction

- Processing

- Applications

- Polycarbonate is a clear and relatively tough plastic used to make shatterproof windows, lenses and even helmets. It is also used to make compact discs.

- Sample preparation

- To induce crazing in polycarbonate, acetone is used. This results in the otherwise tough material becoming very brittle

- Technique

- Scanning electron microscopy (SEM)

- Length bar

- 80 μm

- Further information

- The fracture surface shows fibrils of oriented polymer which are the remnants of crazes. Crazes are both a precursor to cracking and a toughening mechanism in stressed polymers. They only form when a certain critical tensile stress has been attained and form perpendicular to the largest tensile principal stress. They are very fine crack-like projections from the fracture surface but are bridged by even finer material, giving approximately 50% voids. It is these fibrils which interfere with light in an otherwise transparent polymer to make the crazing visible as a whitening of the strained material. The surface ridging, parallel to the principal stress, is a consequence of strain-induced crystallisation during the cold drawing of the polycarbonate.

- Contributor

- J A Curran

- Organisation

- Department of Materials Science and Metallurgy, University of Cambridge

- Date

- 03/10/02

- Licence for re-use

Attribution-NonCommercial-ShareAlike 4.0 International

Attribution-NonCommercial-ShareAlike 4.0 International- Related micrographs