Micrograph Library

Browse the libraryAdvanced searchSystemsCompositionsTechniquesKeywordsPhase diagramsHelpPreferencesAbout the micrograph libraryTerms of useContribute micrographs!FeedbackLinksCredits Print this page

Full Record for Micrograph 729

[305 KB]

View micrograph

.. in new window

View micrograph and record

.. in new window

You can also view and download the micrographs on Flickr

- Micrograph no

- 729

- Brief description

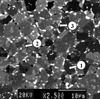

- Ni-Superalloy, exposed microstructure

- Keywords

- nickel

- Categories

- Metal or alloy

- System

- Ni-X

- Composition

- Ni, Cr 14.4-15.2, Co 13-18, Mo 3.5-4.5, Al 3.0-3.3, Ti 4.2-4.8, Ta 2.5, Zr 0.05-0.07, C 0.05, B 0.01-0.03 (wt%) (Ni-Superalloy)

- Standard codes

- Reaction

- Processing

- Exposed at 800°C for 2 500 hours.

- Applications

- Discs are used for high pressure and intermediate pressure turbine discs in Trent 800/900 series gas turbine engines.

- Sample preparation

- Ground to 4000 Grade SiC paper and then polished at 6 <span class="symbol">m</span>m 3 minutes, 1 <span class="symbol">m</span>m 5 minutes, Colloidal silica 10 minutes.

- Technique

- Scanning electron microscopy (SEM) in backscattered electron imaging (BEI) mode

- Length bar

- 10 μm

- Further information

- Following exposure at temperature typical of that found in the modern gas turbine engine, there exist two white phases, one with intergranular distribution and the other smaller particles, apparently randomly distributed. The larger semi-continuous intergranular phase is likely to be either the M23C6 carbide or the deleterious TCP phase, s. Previous work has concluded that this phase is indeed s, which is detrimental to mechanical strength, in particular creep life by embrittlement of the grain boundaries.

Region 1: g matrix

Region 2: g' particle

Region 3: Topologically close packed phase, s

View schematic diagram of g' microstructure - Contributor

- R J Mitchell

- Organisation

- Rolls-Royce University Technology Centre, Department of Materials Science and Metallurgy, University of Cambridge

- Date

- 05/03/03

- Licence for re-use

Attribution-NonCommercial-ShareAlike 4.0 International

Attribution-NonCommercial-ShareAlike 4.0 International- Related micrographs

- Micrograph 724: Ni-Superalloy, as-extruded microstructure (10 μm)

- Micrograph 725: Ni-Superalloy, as-extruded microstructure (10 μm)

- Micrograph 726: Ni-Superalloy, heat treated above gamma-prime solvus (10 μm)

- Micrograph 727: Ni-Superalloy, heat treated above gamma-prime solvus (100 nm)

- Micrograph 728: Ni-Superalloy, heat treated above gamma-prime solvus (10 μm)

- Micrograph 734: Ni-Superalloy, as-extruded microstructure (20 μm)