Micrograph Library

Browse the libraryAdvanced searchSystemsCompositionsTechniquesKeywordsPhase diagramsHelpPreferencesAbout the micrograph libraryTerms of useContribute micrographs!FeedbackLinksCredits Print this page

Micrograph 727 and full record

- Micrograph no

- 727

- Brief description

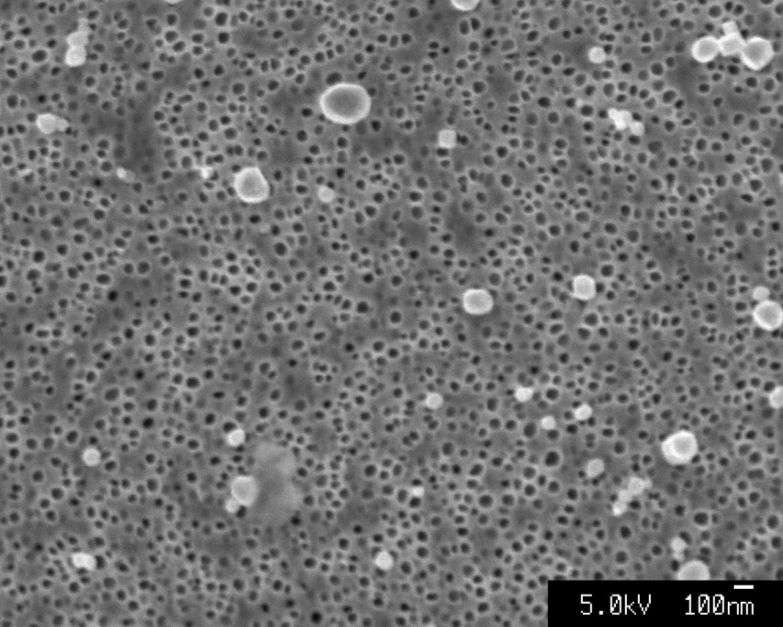

- Ni-Superalloy, heat treated above gamma-prime solvus

- Keywords

- nickel

- Categories

- Metal or alloy

- System

- Ni-X

- Composition

- Ni, Cr 14.4-15.2, Co 13-18, Mo 3.5-4.5, Al 3.0-3.3, Ti 4.2-4.8, Ta 2.5, Zr 0.05-0.07, C 0.05, B 0.01-0.03 (wt%) (Ni-Superalloy)

- Standard codes

- Reaction

- Processing

- Heat treated at 1200ºC for one hour, forced air cool.

- Applications

- Discs are used for high pressure and intermediate pressure turbine discs in Trent 800/900 series gas turbine engines.

- Sample preparation

- Ground to 4000 Grade SiC paper and then polished at 6 <span class="symbol">m</span>m 3 minutes, 1 <span class="symbol">m</span>m 5 minutes, Colloidal silica 10 minutes. Etched using a ‘Nimonic’ etch which preferentially attacks <span class="symbol">g</span>'.

- Technique

- Field emission gun scanning electron microscopy (FEGSEM) in secondary electron imaging (SEI) mode

- Length bar

- 100 nm

- Further information

- Micrograph shows a close up of the secondary g' present within the centre of g grains. This form of g' grows with prolonged exposure to temperature and forms the blocky primary g' found on the grain boundaries.

View schematic diagram of g' microstructure - Contributor

- R J Mitchell

- Organisation

- Rolls-Royce University Technology Centre, Department of Materials Science and Metallurgy, University of Cambridge

- Date

- 05/03/03

- Licence for re-use

Attribution-NonCommercial-ShareAlike 4.0 International

Attribution-NonCommercial-ShareAlike 4.0 International- Related micrographs

- Micrograph 724: Ni-Superalloy, as-extruded microstructure (10 μm)

- Micrograph 725: Ni-Superalloy, as-extruded microstructure (10 μm)

- Micrograph 726: Ni-Superalloy, heat treated above gamma-prime solvus (10 μm)

- Micrograph 728: Ni-Superalloy, heat treated above gamma-prime solvus (10 μm)

- Micrograph 729: Ni-Superalloy, exposed microstructure (10 μm)

- Micrograph 734: Ni-Superalloy, as-extruded microstructure (20 μm)

View image alone .. in a new window

Help is available on downloading images