Electromigration damage

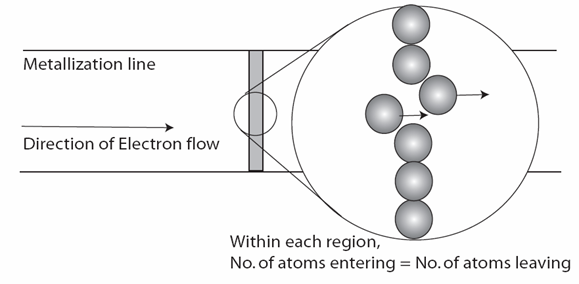

Electromigration is the mass transport in a metallic conductor due to the momentum transfer between conducting electrons and diffusing metal atoms. Uniform electromigration within the metallization lines, if it could be maintained, would not be damaging: in steady-state, no damage should be observed other than at the beginning and end of the metallization line. This is because along the metallization line the number of atoms arriving in a given local volume is equal to the number of atoms leaving the volume, as shown in the diagram below.

Damage to the metallization lines is caused by divergences in atomic flux. When the amounts of matter leaving and entering a given volume are unequal, the associated accumulation or loss of material results in damage.

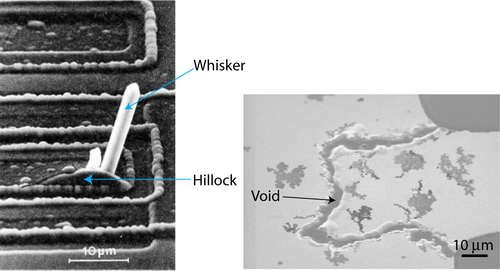

When atomic flux into a region is greater than the flux leaving it, the matter accumulates in the form of a hillock or a whisker. If the flux leaving the region is greater than the flux entering, the depletion of matter ultimately leads to a void. These features are shown in the SEM micrographs below.

Source of images: (left) Microelectronic Materials by CRM Grovenor, IOP Publishing Ltd, Bristol (UK); (right) Dr Lo Veng Cheong

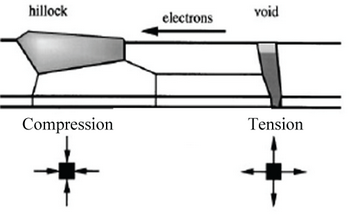

Regions of void formation are usually associated with neighbouring regions of material accumulation, as atoms are transported from one region to the other. Stresses develop within the metallization line as a result of the mass transport.

Source of image: O. Kraft, J.E. Sanchez Jr., M. Bauer, E. Arzt: Quantitative analysis of electromigration damage in Al-based conductor lines. J. Mat. Res. 12 (1997) p.2027-2037.

A stress gradient builds up within the metallic line and opposes the electromigration force. The formation of voids and hillocks partially relieves these stresses. A void forms to relieve tensile stresses, whilst hillock growth relieves compressive stresses.

The growth of voids and hillocks can be viewed in the videos below:

DoITPoMS standard terms of use

Video showing hillock growth (wide metallization lines)

Video showing void growth and migration (wide metallization lines)

Video showing void growth (modern, narrow metallization lines)

Voids and hillocks are detrimental to the metallization lines because a growing hillock could come into contact with other metallization lines resulting in a short circuit, an unintended pathway for the electricity to flow. As a void grows, the effective cross-sectional area of the metallization line decreases. This results in both an increase in resistance and current density within the system. The void ultimately leads to an open circuit when no material bridges across it.

These effects disrupt the intended functioning of the integrated circuit and result in failure. The nature of a microprocessor chip makes repair impossible and the failed chip has to be replaced.