How do fibres affect the Weibull modulus?

In fibre-reinforced polymers, such as carbon fibre-reinforced epoxy resin, and in fibre-reinforced ceramics, the most likely cause of failure is brittle fracture. Therefore, for such materials, a Weibull statistical approach can be used to assess fracture behaviour - see the relevant Brittle Fracture TLP web page for more information on this method.

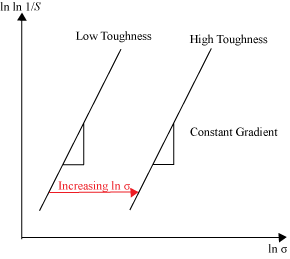

For brittle materials, we might expect that for a particular flaw size, \( a \), the fracture strength, \( \sigma _\text{f} \), might increase if the fracture toughness, \( K_\text{Ic} \), increases, through a formula of the general form \({\sigma _\text{f}} = Y \sqrt {K_\text{Ic}/ a} \), where \( Y \) is a geometrical factor. This would suggest that the distribution in failure stresses for a batch of nominally similar brittle fibre-reinforced materials would have the same Weibull modulus as the unreinforced material, with the distribution in failure stresses increasing because \( K_\text{Ic} \), has increased, as shown below in Figure 9.

Figure 9: Effect of changing the toughness, \( K_\text{Ic} \), on the Weibull distribution of failure strength, \( \sigma _\text{f} \), of a brittle material. \( S \) is the probability of survival at a particular stress, \( \sigma \).

However, this simple approach ignores the fact that toughness is produced in a fibre-reinforced material by processes such as crack deflection, whereby ligaments in the form of fibres are left behind as a crack grows in the matrix. Hence, the fracture resistance, \( R \), of the material is a function of the crack size, i.e., these fibre-reinforced materials exhibit \( R \)-curve behaviour, as also considered here in the Brittle Fracture TLP.

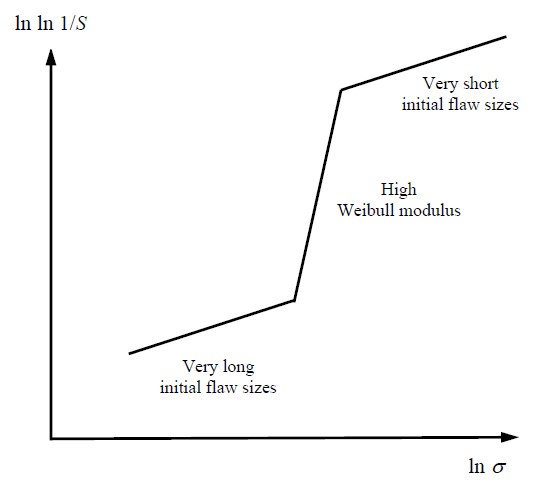

At very low applied stresses, only very large cracks can grow, and will do so catastrophically; at very high applied stresses, only very small cracks can grow, and if they do, they will also do so catastrophically.

At a narrow range of intermediate applied stresses, the cracks can grow in a stable manner: fibres behind the crack tip cease to help in the bridging of the crack, while fibres ahead of the crack tip will come into effect and help to bridge the crack at the crack tip. Hence, in this narrow range of intermediate applied stresses, the Weibull modulus of the fibre-reinforced material is higher than at low applied stresses and high applied stresses because of this stable crack growth behaviour.

This is all demonstrated in the animation below and in the accompanying schematic diagram in Figure 10.

The addition of fibres alters the Weibull plot with a very high Weibull modulus at the tangent point. For example Si3N4 reinforced with fibres increases its Weibull modulus from around 5 to around 20. An increased Weibull modulus is important as it means the part is much more reliable in service so the safety margin can be made smaller and the device can be used at larger applied stresses. Figure 10 shows how the Weibull modulus changes when fibres are added. There is a sudden increase in the probability of failure for a small range of crack lengths corresponding to the tangent point of the r-curve.

Figure 10: Change in Weibull modulus with stress for fibre-reinforced brittle materials