Toughness of chocolate food products

As the experiments shown in the video on the testing of chocolate food products in https://dev.doitpoms.ac.uk/tlplib/toughen/intro.php demonstrate, the toughness of these products depends on their structure and composition, and the temperature at which the toughness is measured.

Chocolate is a material which is itself formed from a number of starting materials such as cocoa solids, cocoa butter, sugar and milk. Cocoa solids and cocoa butter are both derived from cocoa beans. Sugar and milk are optional additions to these two essential ingredients which enable chocolate to exhibit a wide range of sweetness, texture and taste for consumers.

Dark chocolate marketed as 90% or more cocoa can be regarded to a very good approximation as a homogeneous single material at length scales of 1 mm and above.

At refrigerator or freezer temperatures, e.g., 6 °C or less, a bar of dark chocolate behaves as a prototype brittle material. It will fail in bend testing in the elastic regime by fast fracture with what chocolate producers describe as a ‘firm snap’. The force required to fracture a bar will be relatively high, but not so high that an average adult will find it difficult to apply this force.

By contrast, a bar of dark chocolate equilibrated at a temperature of 37 °C (the average body temperature) will begin to deform plastically almost immediately when bend tested because there is little elastic deformation. Eventually, with a moderate force applied, it will break in a tearing manner, indicative of ductile fracture.

Therefore, between 6 °C and 37 °C, it is evident that dark chocolate undergoes a brittle → ductile transition. In this regard, dark chocolate behaves like b.c.c. metals such as ferrite and chromium, and viscoelastic materials such as elastomers. The strain rate is relevant in determining the precise brittle → ductile transition temperature. Just as for metals and viscoelastic materials like silly putty, the higher the strain rate at a given temperature within the brittle → ductile transition regime, the more likely the chocolate is to deform in a brittle manner.

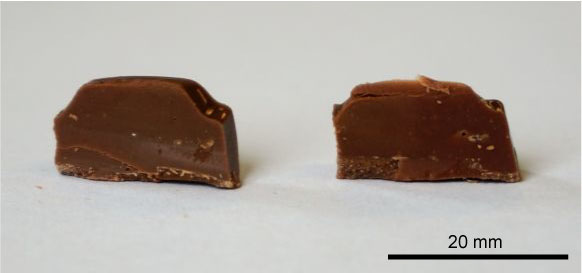

Photograph of a dairy milk bar in cross-section

The data for different types of chocolate products in https://dev.doitpoms.ac.uk/tlplib/toughen/intro.php demonstrate that, at room temperature, the chocolate with the highest cocoa content absorbs the least amount of energy in an impact test, i.e., it is the least tough. Adding milk to the product to make dairy milk chocolate is seen to increase its toughness relative to dark chocolate, both at room temperature and liquid nitrogen temperature.

A further increase at room temperature in the toughness is found when hard particles (nuts) and soft viscoelastic particles (raisins) are added to dairy milk chocolate to produce dairy milk fruit and nut bars.

Photograph of a dairy milk fruit and nut bar in cross-section

However, at liquid nitrogen temperature, the advantage in toughness that dairy milk fruit and nut bars have over dairy milk chocolate is lost because the fruit component is brittle, and the dairy milk chocolate matrix is more stiff than at room temperature. Consequently, the hard particles of nut do not help to increase the surface area of cracks propagating in the chocolate matrix at liquid nitrogen temperature as efficiently as they do at room temperature. Therefore, within experimental error, dairy milk chocolate bars and dairy milk fruit and nut bars at liquid nitrogen temperature are equally tough.

Snickers is a chocolate bar in which a layer of nougat, and a layer of both caramel and peanuts are all encased in a thick surface coating of milk chocolate.

Photograph of a Snickers bar in cross-section

The combined viscoelastic and adhesive behaviour of both the nougat and the caramel enables the Snickers bar to be very tough at room temperature, as determined by the impact test demonstration in https://dev.doitpoms.ac.uk/tlplib/toughen/intro.php where the impact is side on to the Snickers bar.

Interestingly, Snickers is also seen to be reasonably tough at liquid nitrogen temperature in this experiment because of the way in which the complex microstructure of the Snickers bar helps to absorb the impact of the pendulum. An experiment undertaken at much higher rates of strain than attainable with this pendulum experiment would be necessary to have Snickers bars show brittle behaviour at liquid nitrogen temperature, similar to that shown by the dark chocolate in the pendulum experiments.

The principles established from the impact test demonstrations in https://dev.doitpoms.ac.uk/tlplib/toughen/intro.php can be used to study other chocolate food confectionery. Some open-source references to such studies are:

D. Schab, L. Tiedemann, H. Rohm and S. Zahn, Application of a tensile test method to identify the ductile-brittle transition of caramel, 2022, Foods, 11, art. 3218, see the pdf from https://doi.org/10.3390/foods11203218

Y.-Y. Chen, X.-Y. Zhou, S.-H. Qian and J.-H. Yu, Effect of sugar and milk powder addition on the mechanical properties and texture of chocolate, 2022, Journal of Oleo Science, 71,1577-1589, see the pdf from https://doi.org/10.5650/jos.ess22148

S.M.I. Birch, J. Bates, M. Bell, K.A. Christofidou, C.L. Corkhill, V. Hearnden, E.A. Lopez, L.C. Mason, A. Southworth and J.S. Dean, Bending bad—testing caramel wafer bars (#TestATunnocks), 2021, Physics Education, 56, art. 055002, see the pdf from https://doi.org/10.1088/1361-6552/abfece

D. Bikos, G. Samaras, P. Cann, M. Masen, Y. Hardalupas, C. Hartmann, J. Vieira and M.N. Charalambides, Effect of micro-aeration on the mechanical behaviour of chocolates and implications for oral processing, 2021, Food and Function, 12, 4864-4886, see the pdf from https://doi.org/10.1039/d1fo00045d